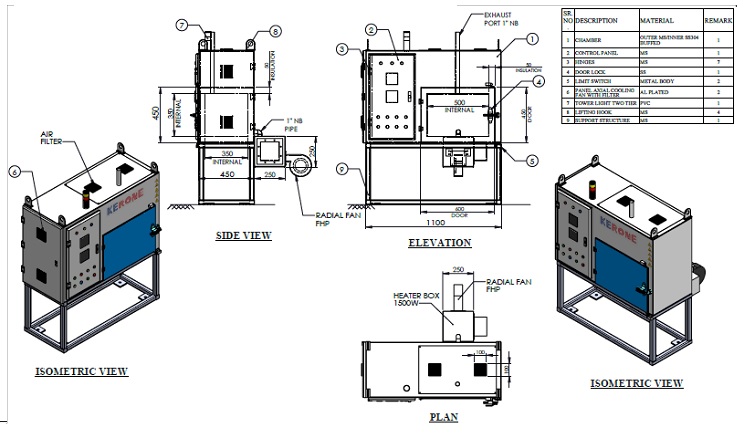

MICROWAVE RUBBER MOULD PRE-HEATING SYSTEMS

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

Kerone is an organization that helps the rubber manufactures and processors with its high quality and technically advanced electromagnetic based heating solution powered by microwave heating. Microwave heating technology has the capability that it penetrates within the rubber material under process and energizes the water molecules present within, this results in very high quality processing in shorter time. As rubber is a poor conductor to heat, this process is very effective. Our preheating solutions provide great benefit to our clients as the high built quality and technical advancements make our solutions more efficient and economical.

Preheating is the process that is performed on rubbers before moulding and vulcanization, the preheated rubber has lower inner tension hence the process becomes more fluent, the time required for the processing is reduced. Pre-heated rubber reduces the curing time and allows the rubber to flow easily and fill the mold cavity efficiently. Pre-heating reduces the vulcanization time by approximately 40%. Kerone’s microwave based heating solutions are designed to adhere to the client’s requirement. Microwave pre-heating systems can be designed for a continuous line or a batch type oven, for which Kerone provides the utmost support and solution with economy of scale.

KERONE Engineering Solutions Ltd. is a pioneer in application and implementing engineering solutions with its vast experience and team of professionals. Since last 42 years, it has been into designing, manufacturing & installing of Industrial machinery for various processing needs. The engineers & professionals at KERONE have in depth knowledge of different heating technologies and provide solutions applying them in a huge no. of Industrial machines.

- Longer functional life

- Low and easy maintenance

- Dense construction

- Quick and Easy installation

- Precisely designed and engineered

- Hassle-free functioning

- Longer service life

- Rugged construction

- High durability

- Energy and Cost efficient

- Power saving

- Efficient performance

- Fast and uniform heating

- Selective heating

- Direct utilization of large-sized feedstocks

- Treatment of non-homogeneous wastes

- Waste reduction and material recovery

- Better production quality

- New materials and products

- Energy efficiency

- Overall cost effectiveness/savings

- Improved process control

- Ability to operate from an electrical source