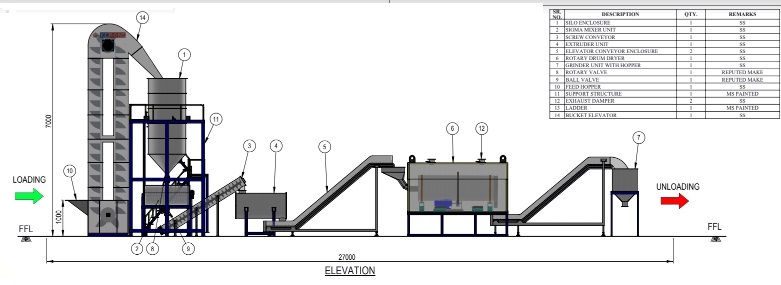

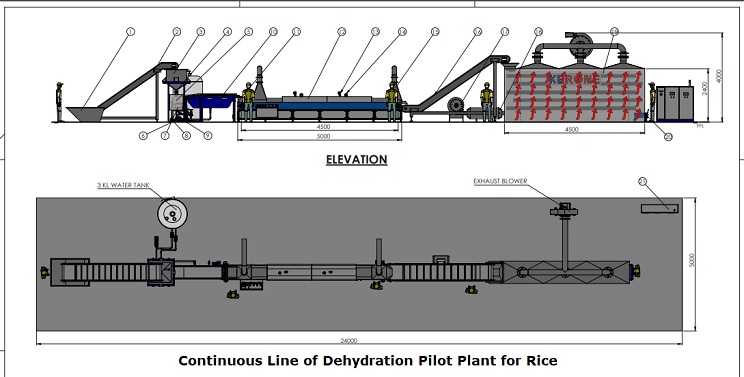

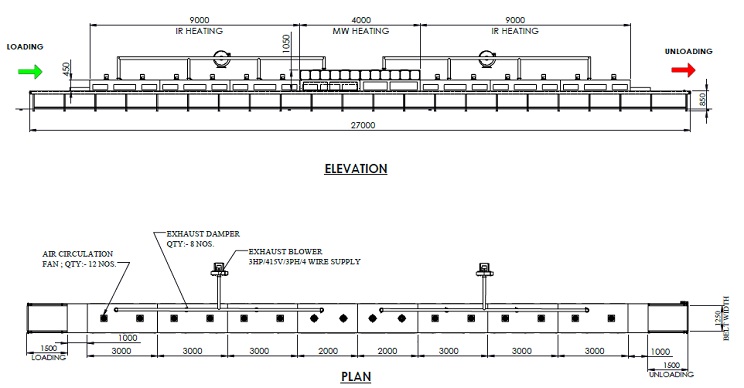

Processing / Production Line

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

Kerone had started its journey as a heating equipment manufacturer back in 1976, since that time we have witnessed plethora of changes in overall industrial ecosystem. To match the pace of industrial engineering requirements and answer the shift in the paradigm of industrial engineering solution needs, at Kerone two decades back we have setup a dedicated unit that would take care processing/production line requirements. Our team of expert study, perform the maths, design & develop prototype, manufacture complete machinery and help you in machine operation and maintenance. With Kerone you can rest assured for your next production plant setup, it will meet all the expected regulations and quality & efficiency requirements.

As production line manufacturer we understand that every production process demands specific attention while machinery needs to be chooses. Entire process is sub divided in small executable processes, which flows consequently in defined scientific manner, this demands the carefully studying the process and breaking down same in sub processes. In general, every manufacturing process is different however, still we can sub divide the whole production process in assembly line steps such as :

1. Material handling: Transfer of material from one place to another

2. Pre-processing: Pre- heating, pre-drying, filtering, cleaning and ETC.

3. Material feeding

4. Processing steps: Varies depending upon the manufacturing need, there are few common steps those are heating, Mixing, Compression, curing, blending, grinding, pressing, drying, crushing, smelting, refining, coating and ETC

5. Output: Processed material are made ready for the packaging or storage, this step can have various types such as screwing, tableting, pumping and ETC

6. Quality inspection and quality check: Final product quality assurance is performed on final stage before packaging or dispatch. There are also many intermediate quality check is also recommended.

7. Packaging and dispatch: Packaging and Quality assurance as interchangeable stages in various production lines.

We have been providing various type of manufacturing lines also well known for providing production plants of various types. As processing/ production plant manufactures we classify the production lines as

1. Batch Production: Producing Similar kind of products together following series of steps.

2. Mass Production: Producing similar goods or products in large scale/quantity, such production line as mostly used in single product manufacturing companies.

3. Mass customised production: This type of production system produces good/products that has different traits and variations.

4. Fully Automated production line: This type of production lines run entirely by the robots and machines, no or minimal human interfaces are required.

We have been helping various form of industries with our accurately crafted production/processing plants, below are few such industries listed .

- Ready to cook food production plants

- Packed food industry

- Bakery production lines

- Dairy and Milk product manufactures

- Paint production plants

- Medical tap manufacturing lines

- Chemical processing plants

- Pharmaceutical companies

- Paper or packaging goods manufacturers