GAS IR HEATING SYSTEMS FOR PERHEATING AND POST HEATING OF SEAM WELDS

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

Seam welding is a process that produces a weld at the faying surfaces of two similar metals. The seam may be a butt joint or an overlap joint and is usually an automated process.

The Preheating of welds at specified temperature and then cooling at slow rate the welds and the base materials, becomes softer weld metal and heat affected zone microstructures with a greater resistance to fabrication hydrogen cracking. The slower cooling rate encourages hydrogen diffusion from the weld area by extending the time period over which it is at elevated temperature (particularly the time at temperatures above approximately 100°C). The Infrared heating system becomes very much suitable as it heats the surface of both the weld and base material very quickly without waste of any time and hence resulting in or allowing slower rate of cooling that can be applied.

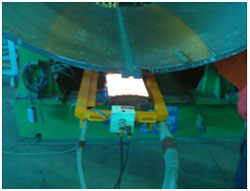

At KERONE we have enormous amount of experience in designing gas infrared (IR) heating system for the varying specialized need of both preheating and post heating requirements such as Seam welds, arc welds and others. Gas Infrared (IF) heating system designed for the preheating and postheating of seam welds are strictly as per the clients demand with best of the quality material and digital control panels.

General feature that Gas IR Heating Systems for Preheating and Post Heating of Seam Welds designed by us offer are

- Extensive operational life

- Low and easy maintenance

- Dense construction

- Quick and Easy installation

- Precisely designed and engineered

- Hassle-free functioning

- Longer service life

- Rugged construction

- High durability

- Energy and Cost efficient

- Power saving

- Efficient performance