Tubular Heaters

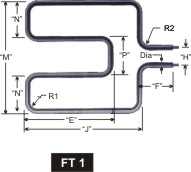

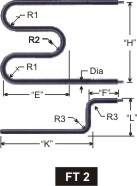

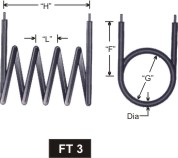

Tubular heating elements of Kerone are the most versatile and the best suited solutions to a large number of applications. Kerone�s tubular elements are factory-configured to almost any shape or size. Custom bending diameters can be made upon request. Typically using steel, stainless steel, Incoloy, inconel or titanium alloys, tubular elements are often regarded as the foundation of all heating elements. These heating elements have a strong outer sheath to help protect the heater from physical stress and uses high quality alloys to allow efficient heat transfer from resistance coil to your heating medium Depending on their rating, sheath and shape, tubular elements are used in a variety of heat applications (conduction, convection, radiation heating) that require process temperatures of up to 750�C (1382�F) to heat liquids, gases and solids. A variety of diameters are available to help adjust watt densities in your application to design these electric heaters for best performance and long life. Standard and custom made terminal pins allow for easy installation and maintenance. Kerone uses high quality magnesium oxide to allow for efficient heat transfer from resistive coil to your heating medium whether it is air, liquid or solid. Bending radiuses are designed with careful expertise to allow for optimal performance within your application.