Radio Frequency Heating Dryer

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

In radio frequency (RF) industrial dryer material to be dried is placed under the RF generator producing the high frequency alternating fields between its two electrodes. This alternating fields causes the polar movement in water molecules this results in friction with in the material water molecules, this friction causes the heating within the material. If sufficient amount of energy is applied it converts the water/ solvent in to steam and evaporate from the material results in drying of material.

The heat is generated within the material hence there is no losses in terms of conduction of heat in surrounding, radio frequency (RF) industrial dryers are highly controllable as the rate of heat production is proportion of radio frequency energy supplied to the materials. Radio frequency industrial dryers manufactured by Kerone help in achieving exceptional output quality of the dried material as the RF dryers are designed to eliminate any type of losses, so that the material is uniformly heated to desired level.

Kerone is holding vast experience in designing, manufacturing and installation of customized Radio frequency (RF) industrial dryers for various industrial applications based on the need and suitability of client’s process requirements. The radio frequency (RF) dryers manufactured in Kerone are strictly follow the defined international standards.

- Radio Frequency heats items straightforwardly and through the thickness of the item. This results in quicker drying.

- Radio Frequency heats from inner surface material and not much constraint with its conducting ability.

- No overheating of material under process

- Distinctive materials heat at diverse rates so it is conceivable to high temperature one and only piece of a composite material or to dry a covering without warming the substrate. This enhances item quality by not heating touchy materials.

- Spontaneous ON/OFF control

- Environmental friendly and very clean process.

- Selective heating can be achieved as the heating happens from within.

- Radio Frequency Heater/Dryers save operational cost by saving time, energy and increased controlled heating

- Uniform heating at the desired speed

- Uniform level of moisture in output material as the wetter areas observes the more RF energy and results in more evaporation.

- The load may be supported by electrodes or conveyed under or between them. Self-supporting webs or strands need not touch anything, thus avoiding surface marking and contamination.

- Designed to handle wide range of Products.

- PLC control with fault identification.

- Low Maintenance.

- Superior quality processed product at highest rate of production.

- Flexible, accurate and effective at low rates of energy utilization.

- Meets appropriate regulations all through the world.

- Batch Type Front opening Radio Frequency (RF) Heater/ dryers.

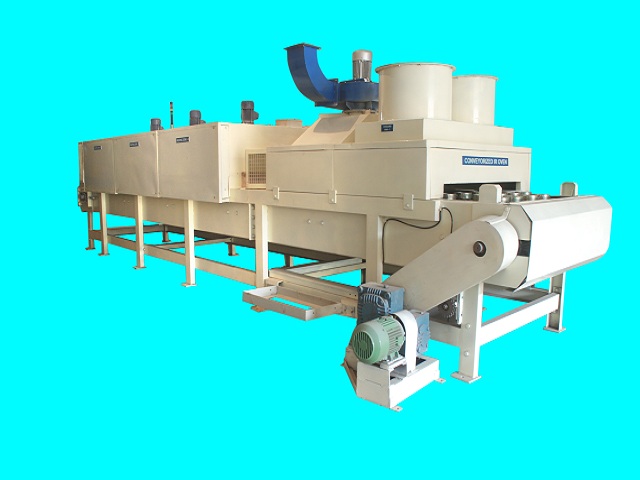

- Conveyorized continuous Radio Frequency (RF) heaters/dryers.

- Drying of wood pulp or paper in the process.

- Drying of meal, flour, grains, seeds, beans.

- Drying of textile yarns and fabric.

- Drying of ceramic.

- Drying of water-based coatings.

- Drying of inks and adhesives.

- Drying and moisture from webs, sheets, & boards.

- Drying and moisture from bulk materials.

- Drying of fiberglass yarn.

- Drying water-based inks.

Q1. How does a radio frequency heating dryer work?

It uses RF waves to heat materials volumetrically, offering deep penetration and uniform drying.

Q2. What industries benefit from RF heating dryers?Food, textiles, pharmaceuticals, chemicals, and biomass industries use RF dryers for consistent and controlled drying.

Q3. What is the advantage of RF drying compared to hot air drying?RF drying provides faster core heating, lower energy loss, and better quality retention.

Q4. Are RF dryers suitable for moisture-sensitive products?Yes, RF technology prevents surface overheating, making it ideal for heat-sensitive materials.

Q5. Can RF heating dryers be customized for specific applications?Yes, RF dryers can be tailored for product size, moisture content, and production capacity.