Cyclone Separators

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

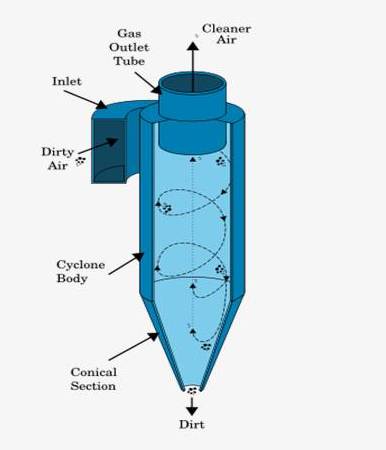

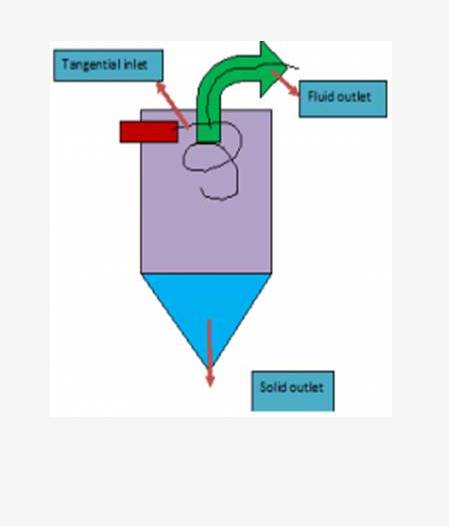

Cyclone Separators is one of many air pollution control devices known as pre-cleaners since they generally remove larger pieces of particulate matter. A cyclone separator is a unit that helps in separating the solids from the air, gas or liquids without need of any filtering unit. The cyclone separator operates on the principle of centrifugal force, its typical operating steps are:

- The suspensions of a solid gas usually air is introduced tangentially at a very high velocity so that rotary movement takes place within the vessel.

- The fluid is removed from the central out let at the top.

- The rotary flow within the cyclone separator causes the particles to react by centrifugal force.

- The solids are thrown out to the walls, there after it falls to the conical base and discharge through solids outlet.

- High performance

- Highly controllable

- Built with the high quality stainless steel material or special Alloys.

- Personalized structure design

- Corrosion free

- Tailor made to fit your requirements.

- Highly controllable

- Very efficient

- Large-scale Serialization

Cyclones are basically used as pollution control and purify these pollutants and flue gas

- Abrasives

- Coolant mists

- Explosive media

- Fine powders

- Metalworking chips

- Toxic media

- Various other production plant exhausts.