Coating and Impregnation Plant

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

Coating and impregnation has increased its demand in market over time, Coating is a method of applying a coat of a liquid on a solid material by way of absorption. Coating also used for applying a fine powdered coat on the solid core using a liquid sticker kind of approach. Often the solid material is coated to protect it from the dust, chemical reaction, slightly thickening the material; it also results in the increase in the life of material. Impregnation is also achieved by the similar kind of process that is followed for coating and the equipment used. Impregnation is to convert the liquid into solid granules; it dries out the liquid content the solid granule structure left behind. With a suitable formulation this can be used to deliver a liquid active material that can be released on application. Impregnation is useful for getting a solid granule from a liquid active.

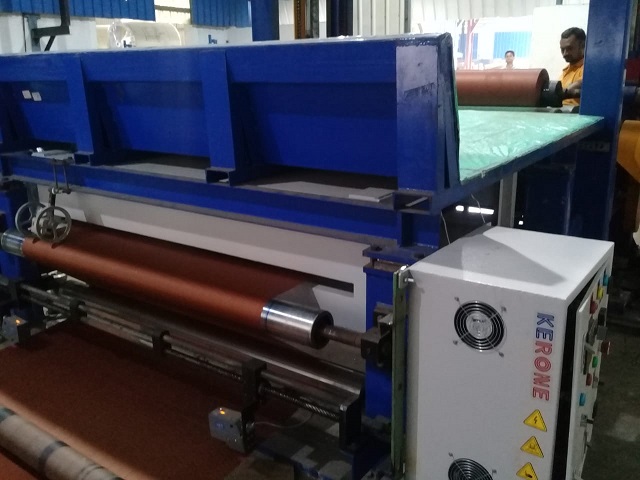

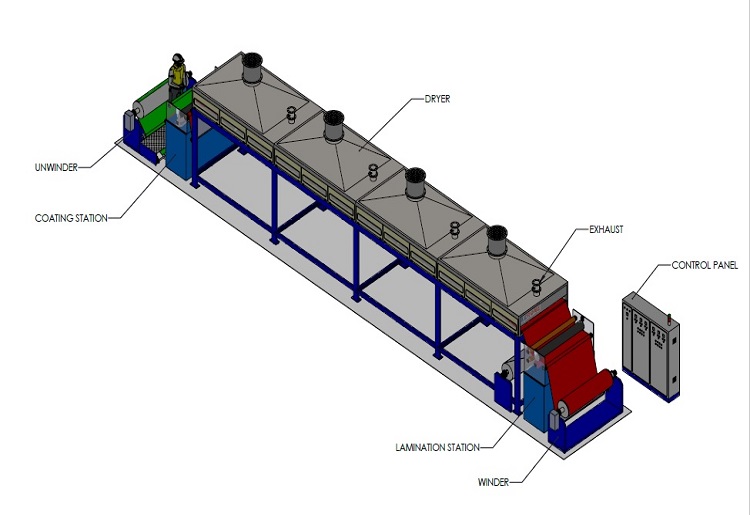

We at KERONE design and manufacture various types of coating and impregnation dyers, as the dryer is most critical to achieve best and efficient result hence we take all the precision and design with the care to avail the best possible result in coating and impregnation plant. We design and built solution for various type of coating

Application of Coating Plant

- PVC / Polyurethane Coating for making of synthetic leather

- Coating plant for Silicon coating on Paper

- Coating Plant for Emery Coating on Paper / Cloth etc ( Coated abrasive manufacturing plant )

- Coating plant for manufacturing Fax Paper / Thermal Paper

- Coating Plant for manufacturing Carbonless paper

- Coating Plant for Copper and Aluminum Foil Coating on various material

- Coating Plant for lead coating on M.S. foil

- Coating Drier for special coating on Plastic

- Bitumen Coating on paper

- Teflon Coating on glass-cloth to strengthen the glass

Application of Impregnation Plant

- Paper products like Decorative Laminates, Electric Laminates

- Fabric based Laminates like Cotton Fabric, Silk Fabric, Jute Fabric, glass Fibre, Glass Epoxy laminates, Carbon etc

- Impregnating Plant for Mica Paper Impregnation

- Impregnating Plant for Filter Paper Impregnation

- Impregnation plant for milk powder manufacturing