Fluidised Bed Dryers

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

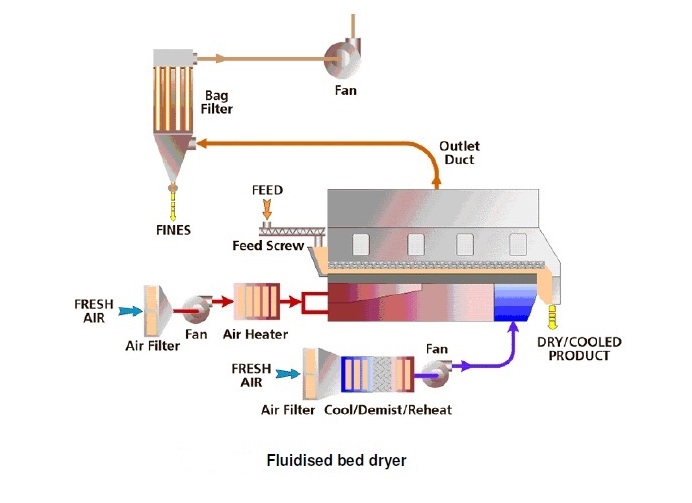

Kerone’s fluidized bed dryers find application in drying of granular materials, pastes, solutions, suspensions, and molten materials in both a batch and a continuous type of model. Kerone provides complete solution from design, manufacturing, erection, commissioning and after installation support. We are having over 45 year experienced in providing the quality product and services in drying and heating segment.

Fluidized bed dryer provided the good solid mixing, high rate of heat and mass transfer and transportation of material. Fluidized bed dryer are more suitable for the drying of fine powder particle sizing from 10 to 2000 mm as compared to other conventional drying methods.

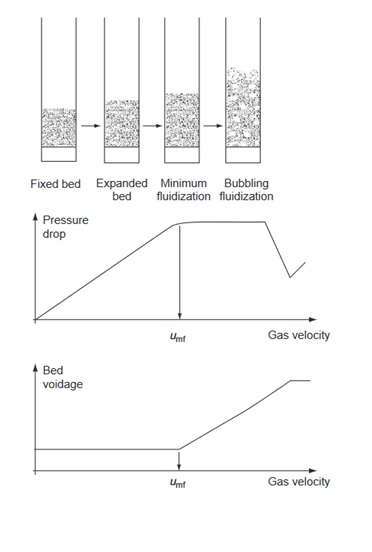

Fluidized bed is achieved by passing a gas stream from the bottom of a bed of particulate solids. At low velocity of gas the bed stays in static condition, and the particles lay on a gas distributor plate. The fluidizing gas passes through the distributor and it is uniformly distributed across the bed. The gas velocity is increased such that to achieve the fluidization of bed, gas velocity at which the bed achieves the fluidization is known as minimum fluidization velocity. A Fluidised bed dryer operates at gas velocity higher than the minimum fluidization velocity of material under processing. This increase in the gas velocity result in suspension of particles under processing in air, this appears as the boiling of solid particles of material under processing.

- Materials dried in a constant-rate drying

- Drying of material with low moisture content, under a relatively low temperature.

- Suitable for granules or crystallized materials as there is no damage to particles.

- High drying efficiency

- Modular Design

- Uniform Drying with reducing Drying time

- Provides extended residence times

- Fireproof Construction

- Easy to remove/change heat exchanger

- Flexibility of residence time and temperatures

Kerones’ fluidized bed dryers are commonly used in processing of:

- Chemicals

- Carbohydrates

- Foodstuff

- Biomaterials

- Beverage Products

- Ceramics

- Pharmaceuticals in Powder or Agglomerated Form

- Health- Care Products

- Pesticides and Agrochemicals

- Dyestuffs and Pigments

- Detergents and Surface-Active Agents

- Fertilizers

- Polymer and Resins

- Tannins

- Products for Calcination

- Combustion

- Incineration

- Waste Management Processes

- Environmental Protection Pro- Cesses

Q1. What is a fluidised bed dryer?

It uses upward-flowing hot air to suspend and dry particles for fast and uniform moisture removal.

Q2. Which materials are suitable for fluidised bed drying?Granules, crystals, powders, cereals, chemicals, and pharmaceutical ingredients.

Q3. Why choose a fluidised bed dryer?It ensures high heat-transfer efficiency and consistent product quality.

Q4. Are fluidised bed dryers energy-efficient?Yes, recirculated air and controlled airflow reduce energy consumption.

Q5. Does it support continuous operation?Yes, continuous fluidised bed models are available for large-scale production.