- Home

- About

- Products

- Industrial Dryers

- Microwave Heating Dryer

- Radio Frequency Heating Dryer

- Conventional Heating Dryer

- Infrared Dryers

- Hot Air Dryer- Stenter

- Flash Dryer

- Spray Dryer

- Imperial and Band Dryers

- Box Dryer

- Heat Pump Dryers

- Fish Dryer

- Microwave Spices Dryer

- Drum Dryers

- Spiral Conveyor Dryers

- Tunnel Dryer

- Food Dryers

- Grain Dryers

- Freeze Dryers

- Cylinders Dryers

- Fluidised Bed Dryers

- Coal / Briquette Dryer

- Rotary Dryers

- Tower Dryers

- Tray Dryers

- ROTARY DRYERS

- BIOMASS ROTARY DRYER MACHINE

- COCONUT & PALM SLAG ROTARY DRYER

- COAL ROTARY DRYER

- COAL STEAM TYPE ROTARY DRYER

- COCONUT COIR DRYERS

- COW DUNG ROTARY DRYER

- ELEPHANT GRASS DRYER

- ELEPHANT GRASS DRYER

- MINERAL SLAG ROTARY DRUM DRYER

- ORGANIC FERTILIZER PLANT

- PADDLE ROTARY DRYER

- PADDLE STIRRING DRUM ROTARY DRYER

- POULTRY MANURE ROTARY DRYER

- ROTARY DRUM SAWDUST DRYER

- SAND ROTARY DRYER

- THREE CHANNEL DRUM ROTARY DRYER

- COATING LINES

- HOT MELT ADHESIVE MIXING PLANT

- Process Equipments

- COAL / BRIQUETTE DRYERS

- INFRARED PISTON ROD HEATING SYSTEMS

- WET LAID PAPER PLANT / MACHINES

- PROCESSING / PRODUCTION LINE

- MIXING KETTLE

- MICROWAVE RUBBER MOULD PREHEATING SYSTEMS

- MICROWAVE CHEMICAL VAPOUR DEPOSITION SYSTEMS

- MW+IR RUBBER VULCANIZATION LINE

- MICROWAVE DRYERS FOR CHEMICAL POWDER

- DEHYDRATORS

- MICROWAVE MEDICAL WASTE TREATMENT

- DRUM HEATING OVENS

- SLUDGE DRYING SYSTEMS

- Coating And impregnation Plant

- HEATING COOLING SYSTEMS

- STERILIZATION & DISINFESTATIONS SYSTEM

- MICROWAVE HEATING SYSTEMS

- PULP PACKAGING DRYER

- INDUSTRIAL HEATERS

- Fuel Fired Heating System

- INDUSTRIAL HEATING EQUIPMENTS

- HOT AIR GENERATOR

- RADIO FREQUENCY HEATING SYSTEMS

- Umbrella IR Dryer

- Electric Oven HT LT Motors

- Microwave Rubber curing

- plastic Annealing Oven

- PLC & AUTOMATION PANEL

- Infrared Paper Coating & Drying

- INFRARED HEATING EQUIPMENTS

- IR Dryer

- Web Dryer

- Hot Air Dryer

- Flash Cure Dryers

- IR Flash Cure

- IR Curing Unit

- Industrial Gas Burner

- Tunnel Ovens

- Printing Drying Oven

- Conveyor Oven

- Infrared Oven

- Flat Belt Conveyorised Oven

- Flat Belt Ovens

- Batch Ovens

- Web Dryer/Sheet Oven

- Tunnel/Clam Shell Ovens

- IR Booster Ovens

- Overhead Conveyor Ovens

- Portable Infrared Heating Systems

- GAS INFRARED HEATING SYSTEM

- Infrared Surface Heating System

- INFRARED HEATING SYSTEM

- INFRARED HEATERS

- Ceramic Infrared Heaters

- Colour Changing Infrared Heaters

- Ceramic Flat Infrared Heaters

- Insulated Ceramic Infrared Heaters

- Super High Temperature Black Infrared Heaters

- Thermocouple Ceramic Infrared Heaters

- High performance Infrared Heaters

- Medium Wave Infrared Heaters

- Medium Wave Infrared Heating Moulds

- Twin Tube Medium Wave Infrared Heater

- Fast Medium Wave Infrared Heater

- Short Wave Infrared heaters

- Short Wave Infrared Module

- Twin Tube Short Wave Infrared Module

- LAB EQUIPMENTS

- B.O.D Incubator

- Environmental Test Chamber

- Blood bank Refrigerators

- Low temperature water bath

- Dehumidifiers

- Deep freezers Upto-35 Deg C

- Laminar Air Flow Bench

- Bacteriological Incubator

- Laboratory Oven

- Laboratory Oven Air Draft

- Laboratory Incubator

- Vacuum

- Hot Plates

- Water Bath Thermostatic

- Shaker water Bath

- Serological water Bath

- Flask Shaker

- Muffle Furnace

- U.V.Cabinet

- Dissolution Rate Test Apparatus

- Bulk Density Apparatus

- Melting point Apparatus

- Auto Karl Fischer titration apparatus

- Tablets Disintegration Test Apparatus

- Heating Mantles

- Heating Block(Dry Bath)

- Soxhlet Extraction Heater

- Vertical Autoclave

- Water Still (Distillation Unit)

- Tray Dryers

- Industrial Ovens

- Industrial Dryers

- Application

- Quality policy

- Video Gallery

- Blog

- Technical Resources

- Contact

- Careers

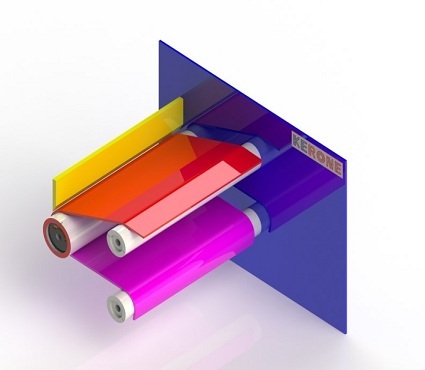

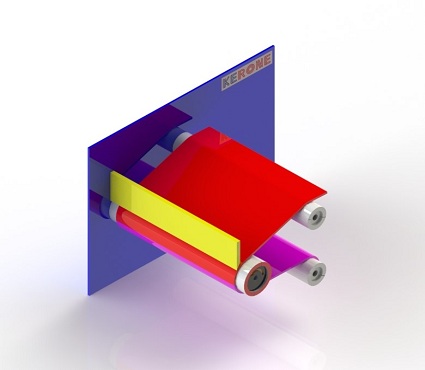

Air Knife Coating Machine

The Air Knife coater, likewise called Air Doctor is a case of an old coating system that is still generally utilized and has a part as a part of the coating process. It was broadly used to successively cover the different layers required for photographic movies in light of the fact that it could apply thin layers from low thickness arrangements. Slide and blind coating on account of enhanced quality, higher rates and multilayer ability supplanted it. It is currently generally used to apply pigmented coatings in the paper business and for 100% solids coating, for example, liquid zinc and aluminum in arousing applications A basic process where the coating is connected to the substrate and the abundance is 'brushed off' by an effective jet from the air knife. This method is regularly utilized for fluid coatings and is especially boisterous

We at KERONE are having 48+ years experience in designing and manufacturing various types of specialized coating and impregnation plants for various industrial processing needs of our clients. We are having immense experience in designing and manufacturing of Air Knife Roll coating machine that can best fit for the size and various processing requirements of the client’s business. The Air Knife Roll coating machines manufactured by KERONE are made with high quality internal and external material by taking discreet efforts for the perfect coat and uniform heat distribution.