Contact Drying- Steam Cylinders/Cans

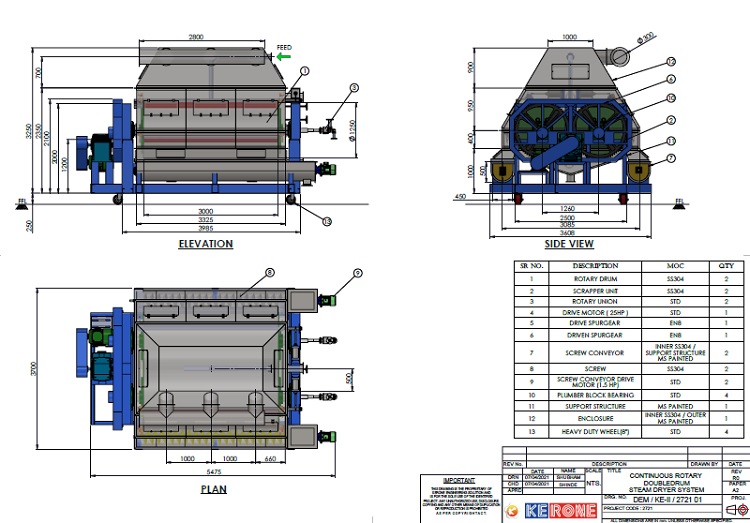

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

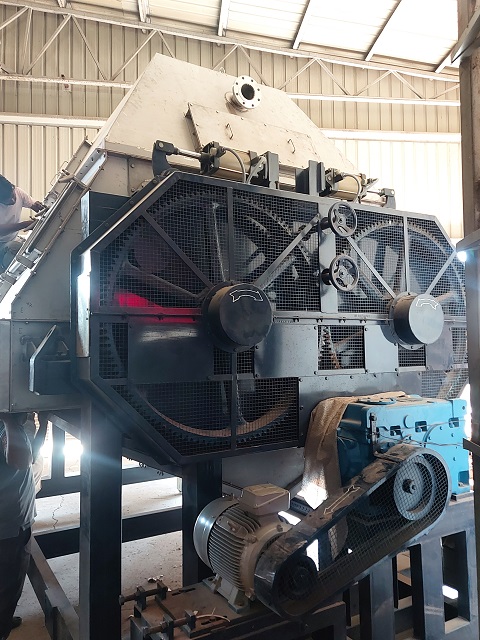

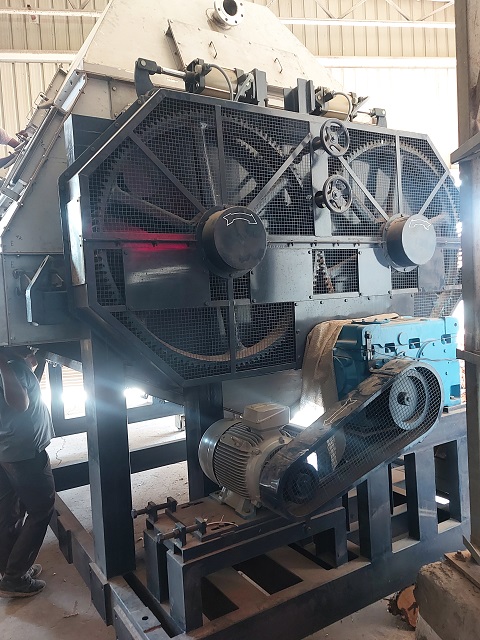

KERONE is having over 48 years experience in designing and manufacturing of various type of Contact Drying- Steam Cylinders/Cans. Our expertise with dryers and drying application, Contact Drying- Steam Cylinders/Cans the simplest and cheapest mode of drying fabrics.

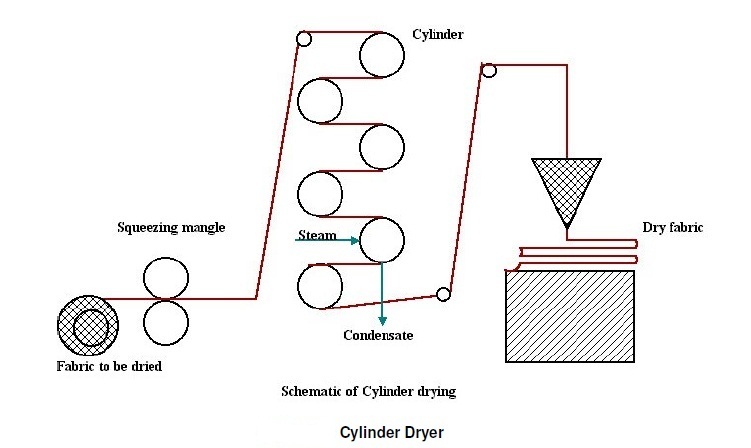

Contact Drying- Steam Cylinders/Cans are primarily employed for transitional drying rather than final drying and for predrying prior to stentering. Fabric/drying material is passed around a series of steam heated cylinders using steam at pressures varying from 35 psi to 65 psi. Cylinders can be used to dry down a wide range of fabrics, but it does give a finish similar to an iron and is therefore unsuitable where a surface effect is present or required. In stenters, the fabric is width wise stretched for width fixation by a series of holding clips or pins mounted on a pair of endless chains.

It is common for steam cylinders to have problems such as leaks at vacuum breakers, air vents, rotating joints and steam traps. This is a direct result of the design of the heating system which relies on passing steam and condensate into and out of each cylinder via a rotating joint. When you have up to maybe 32 such cylinders in a single bank then the potential for leakage is considerable. It is therefore important to initiate a good maintenance regime. For example: periodically checking steam traps using an ultrasonic steam leak detector.

- Melts with wetting property to metal surface, can be flaked

- Closed construction available

- Minimize vapour nuisance

- Avoid dust contamination

- Maintains low RH air blanketing

- For inert gas blanketing

- For maintenance of suction conditions for purposes of operator comfort