Bag House Filter

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

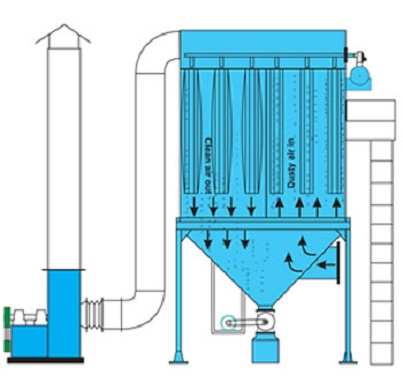

The Bag house or fabric filter is an air pollution controlling mechanical setup; it removes the contaminations from the air/gas released from the industrial processes. KERONE is well-known for designing the filtering units that can best suits to customer and regulatory requirements.

We have experience in manufacturing of following type of Bag house filters:

- Mechanical Shaker Baghouse

- Reverse Air Baghouse

- Reverse Jet Baghouse

Our process equipment division helps the industries with our various scales of process equipments:

Lab Scale: We also produce the process equipments for the very small scale processing such as R&D and laboratory experiments, the lab scale process equipments are made to provide the high level of accuracy. As the name suggests the lab scale process equipments are comparatively smaller in size and capacity but are equipped with the high degree of control and various experimental setting.

Pilot scale: Pilot scale process equipments are for small industrial system, which is operated as the subset of the full-fledged industrial machinery. Pilot scale process equipments are just replica of the large scale process equipment only deference is the size and input capacity which is comparatively less.

Large Scale: Large scale or industrial scale processing equipments are designed and build for the larger production units, these process equipments has lot of features such as easy and automatic handling of materials, also provide high level of functional constancy and ease of operation.

Features:- Robust construction

- Ease of operation

- Corrosion free

- Tailor made to fit your requirements.

- Highly controllable

- Very efficient

- Automotive Industry

- Cement and lime Industry

- Iron and steel Industry

- Melt-shop de-dusting Industry

- Mining Industry

- Oil and gas Industry

- Paper and pulp Industry

- Petrochemical Industry

- Power generation plant Industry

- Sugar Industry