Spiral Conveyor Dryers

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

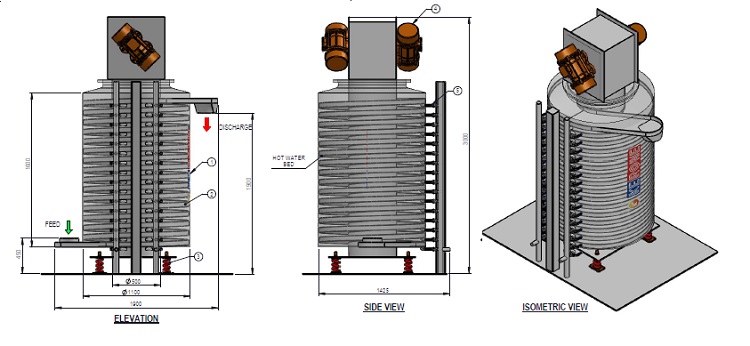

Kerone Spiral Conveyors System are based on a new and innovative technology, offering many features and benefits. Spiral conveyors from KERONE needs less floor space than conventional conveyors and are also faster and more reliable than any elevator or lift. Central to our design is the proprietary slat-type belts with rolling friction and without any sliding movements or wear-strips.

At Kerone, we are having more than 50 years’ experience in helping various types of industries with designing; manufacturing and installation of various types of custom build industrial spiral drying solution. Kerone Spiral dryers are very useful in the automated manufacturing process and can be used to carry various solid items or solid-liquid mixes—from loose materials and manufactured items to finished, packaged products.

Spiral conveyor provides automation of production processes, increase profitability and saving of production space. These conveyor systems have already gained its popularity among food producers.Industrial Spiral Conveyor System offered finds use for handling goods movement involving floor-to-floor handling as well as in specific directions including from top to bottom and from bottom to top.

Spiral conveyor dryer are very completed and can improve the productivity as much as possible in spiral application. Low cost, high efficiency. To breakthrough the bottleneck restriction of production line, improve efficiency and lower costs. Some of its features include can handle different support processes like stirring, mixing, heating and cooling operations at time of conveying; suitable for handling transportation needs of granular materials like mineral powder, cement powder, fly ash, sand, coal and others.

Feature:- Highly flexible Design and Technology.

- Easy Maintenance

- Low cost of operation

- Controlled Pollution Level

- Energy saving

- Easy Operating

- Fast, easy installation

- Food processing

- Agriculture

- Chemical

- Pharmaceutical

- Foundry

Q1. What is a spiral conveyor dryer?

It uses a spiral conveyor belt to dry products gradually in a compact, multi-level structure.

Q2. Why choose spiral drying?It saves space while offering uniform, continuous drying.

Q3. Which materials can be dried?Food products, snacks, chemicals, herbs, and granules.

Q4. Are spiral dryers energy-efficient?Yes, recirculated hot air improves thermal efficiency.

Q5. Can the residence time be controlled?Yes, conveyor speed and temperature settings are fully adjustable.