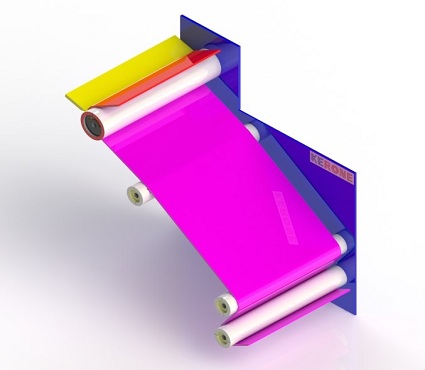

Knife Over Roll Coating Machine

The Knife over roll coater has traditionally been the choice when needing to put down a substantial and level coating of medium to high consistency onto uneven surfaces, for example, materials, fiber glass mats and non woven. Average applications incorporate cast movies, emblazoned and plain deck, fortified plastics, medicinal dressings, material cement coatings

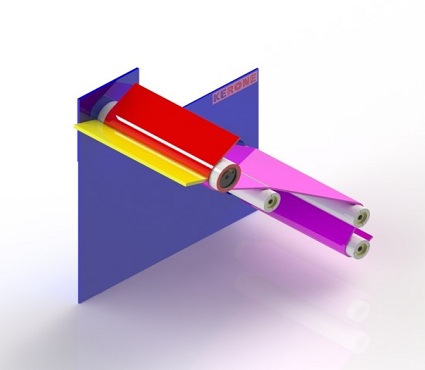

This process depends on a coating being connected to the substrate which then goes through a "gap" between a "knife" and a bolster roller. Contingent upon the wanted impact to the knife is countered by a roller, platen or nothing by any means; in this manner roller knives, platen knives and air knives are recognized. The knife bar of current coating plant is outfitted with a few coating knives and is alterable as per the pistol rule. This encourages a brisk change of the knives, particularly of the roller and the air knife.

Now and again, the sides scrubbers are finished to a shut glue bowl with a front plate, which is fundamental particularly when low-thick coating glues are concerned. Contingent upon the thickness of the cover to be connected, in transit of the knife's design and the consistency of the glue, knives of diverse profiles are utilized.

We at KERONE are having 48+ years experience in designing and manufacturing various types of specialized coating and impregnation plants for various industrial processing needs of our clients. We are having immense experience in designing and manufacturing of Knife Over Roll coating machine that can best fit for the size and various processing requirements of the client’s business. The Knife Over Roll coating machines manufactured by KERONE are made with high quality internal and external material by taking discreet efforts for the perfect coat and uniform heat distribution.