Grain Dryers

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

Grain Dryers are used to dry the grain and prevent them from spoilage during storage. Kerone Engineering Solutions Ltd. is a remarkable and leading Grain Dryer manufacturer in Mumbai, India and also located on the land area of outer country cities.

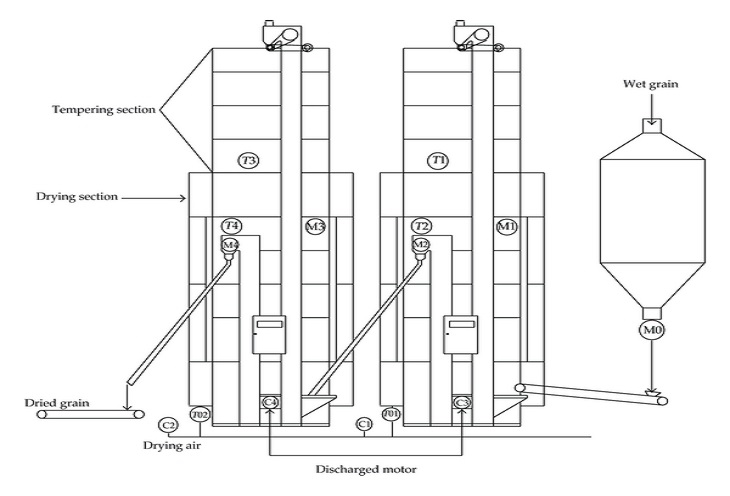

Grain drying is process of drying grain to prevent spoilage during storage. Kerone multi grain dryer is that which uses fuel- or electric-powered processes supplementary to natural ones, including swathing/windrowing for drying by ambient air and sunshine.

Grain drying system is an energetic area of analysis. The performance of a dryer is simulated with computer programs based on mathematical models that represent the phenomena involved in drying: physics, physical chemistry, thermodynamics, and heat and mass transfer. Most recently computer models are utilized to predict product quality by achieving a compromise between drying rate, energy consumption, and grain quality. A typical quality parameter in wheat drying is bread creating quality and germination percentage whose reductions in drying are somewhat related.

Common storage facilities for grain include warehouses, bins, barns, elevators, and silos. It’s important that the storage conditions maintain the quality of the grain. One issue influencing the storability of grains is that the degree of maturity at harvesting. When cereals are harvested at maturity, it dries faster than when it's harvested prematurely. Some grains, particularly corn, which is harvested with high moisture content, must be artificially dried to stop spoilage. High-temperature grain dryers may be used to quickly reduce the moisture content by 5%–10%.

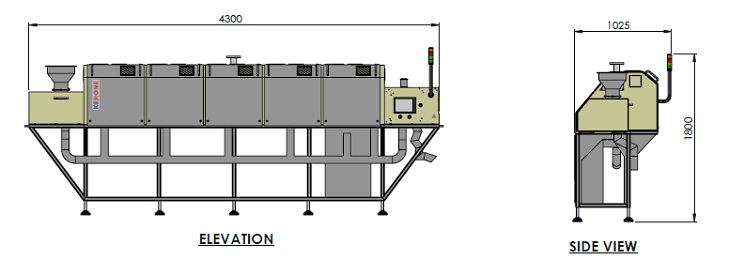

Our team is engaged in producing and engineering extremely qualitative Grain Dryers with the utilization of top quality of material that improved the high and optimum performance and durability of the products.

Our engineers prefer advanced and smart quality of tools and latest technologies with advanced CNC cuttings and bending machines in a very hygiene infrastructure that produces optimum productivity, reliableness, and lasting durability.

FAQsA grain dryer removes moisture from harvested grains to prevent spoilage and improve storage life.

Q2. Which grains can be dried?Paddy, wheat, corn, soybean, pulses, and other cereals.

Q3. Why is grain drying important?It prevents fungal growth, improves quality, and maintains market-grade standards.

Q4. Are grain dryers energy-efficient?Yes, modern systems use controlled airflow and heat recovery for lower energy consumption.

Q5. Do they support continuous operation?Yes, industrial grain dryers offer continuous, high-capacity drying.