Food Dryers or Food Dehydrators

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

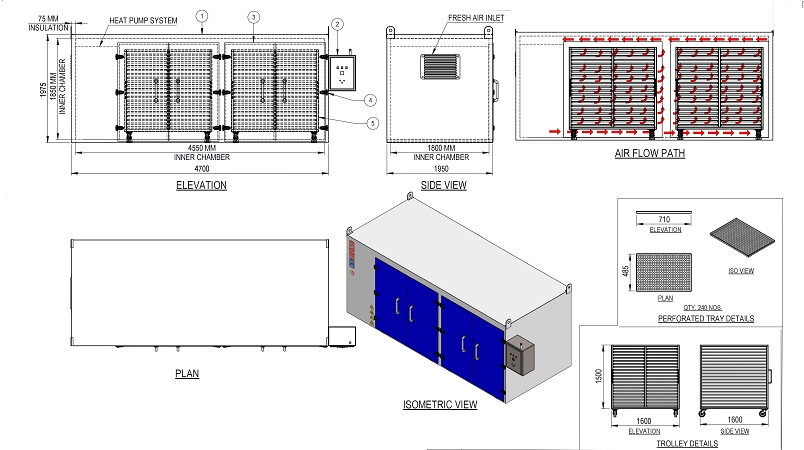

At Kerone, we are having over 48 years’ experience in serving to numerous sorts of industries with designing; producing and installation of various types of custom build industrial drying solution. We facilitate the shopper in selection by understanding the necessity for quality, size; shape and moisture content of the final word dried product have to be taken into contemplation, as well as production setting, construction materials most common stainless steel, energy consumption pattern. The feeding type and amount of material to be fed.

Drying or dehydration—the oldest method of food preservation—is particularly successful in the hot, dry climates found in much of New Mexico. Quite simply, drying removes moisture from food, and moisture is necessary for the bacterial growth that eventually causes spoilage. Successful dehydration depends upon a slow, steady heat supply to confirm that food is dried from the inside to the outside. Most fruits and vegetables should be prepared by blanching—and in some cases by adding preservatives—to enhance color and microbial shelf-life of the dried food. But some fruits, like berries, aren't blanched before drying. Drying is an inexact science. Size of food pieces, relative moisture content of the food, and the method selected all have an effect on the time required to dehydrate a food adequately.

A method of Drying Foods is also sun-dried with or without a solar dehydrator, dried during a gas or electric oven, or dried with a conveyable electrical dehydrator. Dehydrators with thermostats aren't affected by atmospheric condition and allow better control over food quality than sun drying. Clotheslines are an acceptable drying rack for ears of corn.

- Sun drying

- Oven drying

- Solar Dehydrator

- Electric Dehydrator

Kerone design and build the industrial dryers to continuously reproduce the best result for the material under processing, below are the few key feature of our solutions:

- Highly controllable design and technology

- Accurately calculated processing time

- Minimum handling

- Low cost of operation

- Controlled noise level

- Compact construction

- Minimum Maintenance

- Accurately calibrated

- Uniform drying temperature is assured

- Energy saving

- Less fuel consumption

Q1. What are food dryers used for?

They remove moisture from fruits, vegetables, spices, grains, and processed foods.

Q2. Why use food drying equipment?It extends shelf life, preserves nutrients, and improves storage stability.

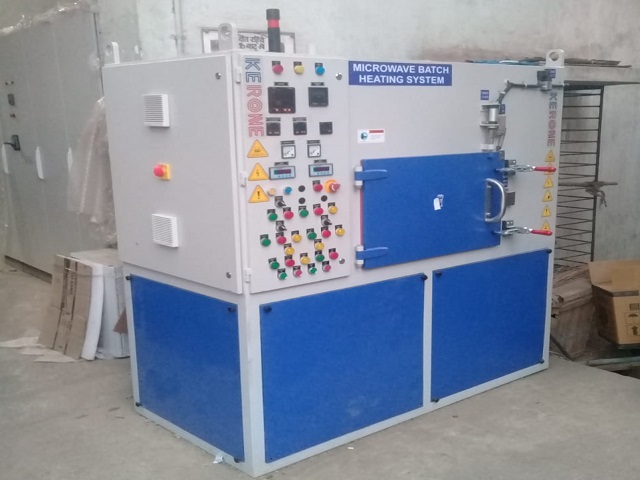

Q3. Which drying technologies are used in food dryers?Hot air, infrared, microwave, heat pump, and freeze drying.

Q4. Are food dryers energy-efficient?Yes, modern systems optimize airflow and heat recovery.

Q5. Is the drying process food-safe?Yes, food-grade materials and hygienic designs ensure safety.