Spray Dryer

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

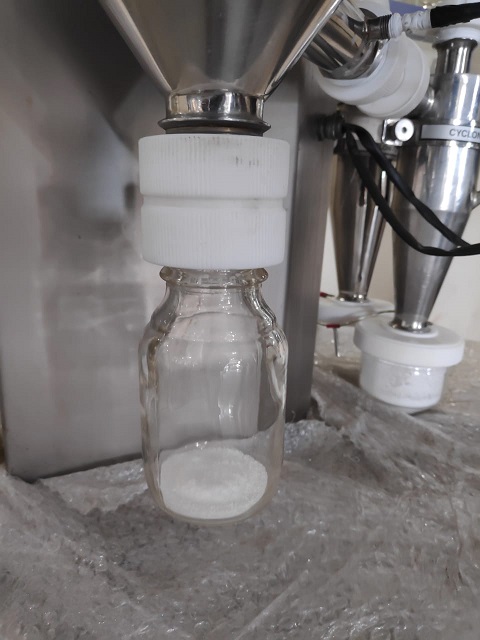

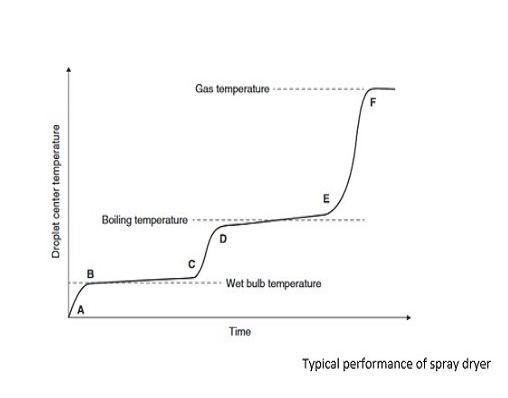

Spray drying is method of dehydrating fluids, solutions and thin slurries, it converts the fluids or slurries to powder form. Liquid or slurry material to be dehydrated is sprayed in the form of a fine droplet dispersion into hot airstream. Both air and material either travel in parallel or counterflow. Drying in spray dryer occurs at very fast rate so that the contact of material to heat is not for longer time hence its does not damage the heat selectivity materials and becomes ideal for drying such materials.

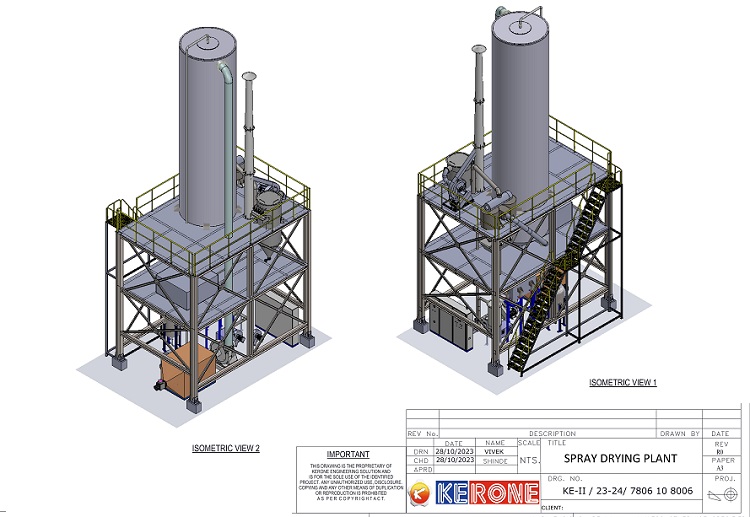

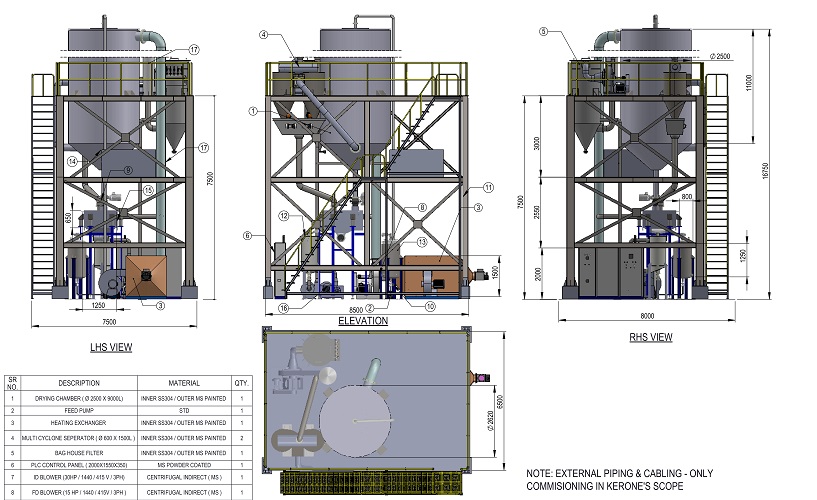

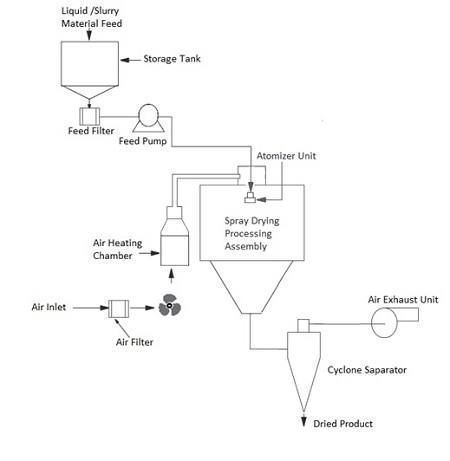

At Kerone, we produce spray dryers that can be fall in various range based on the complexity of design from simple to very complex, all depends on the fluid or slurries under processing. The difference in the designs rare the in atomization, pattern of airstream, air heating systems/technique, and separation and collection unit. Spray dryers mainly comprises of drying chamber, atomization and dispersion means to feed fluid in small droplets into the drying chamber, air heating system, and separation unit to collect dried output.

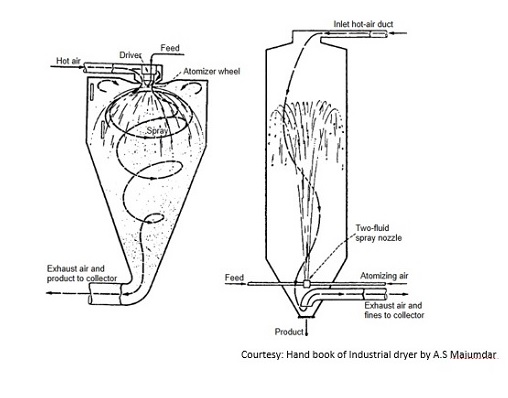

Hot air can be achieved by the means of direct firing of gas or by the means of fuels or uses of heat exchangers. Pressure spray heads, nozzles, and centrifugal atomizers are applied for distribution of the fluid elements. Processed product is separated by using cyclone separators in which the air is applied laterally at the top or settling chamber in which the direction of airflow is reversed to achieve separation of dried products by means of gravity. Below schematic depict both the approaches.

Kerone is having meticulous experience when it comes to design and built spray drying unit that can be utilised for various application in varying industries. So far we have helped tons of or clients with their drying needs. Our team of engineers and quality manufacturing process helps us to achieve the accuracy and product quality.

- Spray Dryers are continuous drying techniques, higher production speed can be achieved.

- Spray dryers are rapid dryer, drying rate is high.

- Product quality can be controlled and maintained in drying process

- Highly controllable drying systems flow of hot air, droplet speed and droplet temperature can be effectively controlled.

- Fine droplets shaped offers more surface area for heat and mass transfer.

- Spray dryer can be used to achieve wide range of production rate.

- Minimum human intervention required hence it reduce the operator/ labour cost.

- Dried product, free flowing product of uniform size and dimension can be achieved.

- Microcontroller based interactive and highly precision control mechanism can be achieved.

- Limited moving parts and no moving parts are in through contact with the product, diminishing corrosion complications.

- A variety of spray dryer designs to meet different product specifications.

- The temperature variation within the drying chamber is relatively small.

- Uniform drying of all type of material fed as input.

- Long-lasting powder coating .

- Multiple drying zones can be provisioned.

- Ability to handle any type of pumpable product .

- Modular assembly for stress-free transport and installation

- Exclusively engineered with measured environment for fast, trouble free drying.

- Air patterns designed for most efficient, safe drying.

- Designed to dry a large range of conditions.

- In dairy production and processing of milk.

- Production of Powdered milk, skimmed milk and whole milk.

- Processing Egg‐based products .

- Production of sweets and ordinary edible acids.

- Processing Coffee/ Tea whiteners.

- Wheat and corn based products in bakery.

- Spray dryers find application in tablet production for drying of liquid to powder.

- Used in production of dye colour, food colours, paint pigments.

- Soap and detergent manufacturing processes utilise the spray dryers.

- Spray dryer find place in fertilizer production like nitrates, ammonium salts, phosphates and others.

- Spray dryers are very useful in drying of citric acid, borax, sodium phosphate, hexamine, gelatine and extracts.

Q1. What is a spray dryer used for?

A spray dryer converts liquid feed into a fine powder through atomization and hot air drying.

Q2. What industries use spray drying technology?Food, pharmaceuticals, chemicals, dairy, and nutraceutical industries rely on spray drying.

Q3. Why choose a spray dryer for powder production?It produces uniform particle sizes, high purity, and stable powders with controlled moisture.

Q4. What feed materials can be sprayed?Solutions, slurries, emulsions, and heat-sensitive liquids can be spray-dried efficiently.

Q5. Are spray dryers scalable for different production needs?Yes, they are available in lab, pilot, and industrial models to suit all capacities.