Polyethylene Wax Processing Plant

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

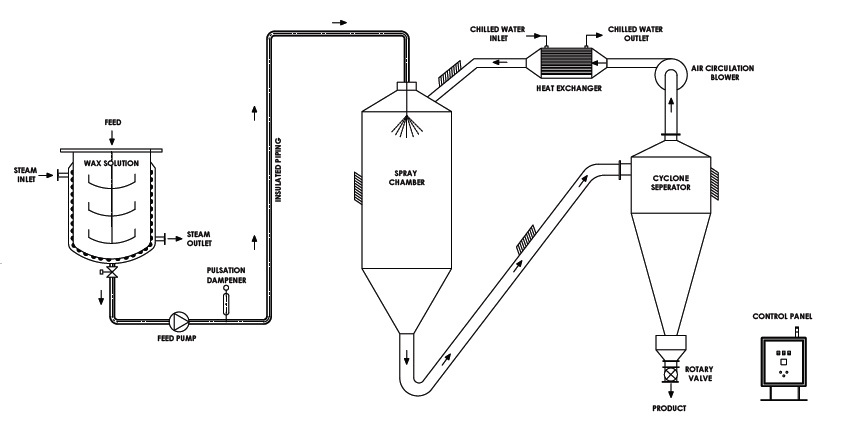

Kerone is having more than 4 decades’ experience in providing simplified, effective and very high quality solution to most of engineering needs; we offer our services from heating solution to entire processing plant. Our engineered products are always to delight our customer with its design, operational efficiency, control mechanism and operational ease. Kerone’s Polyethylene wax processing plants are a state of art technology to produce the highest quality refined Polyethylene Wax. Each component of plant ensures strict quality control process, it is developed to ensure that Polyethylene Wax products are produced with unique properties and consistent quality.

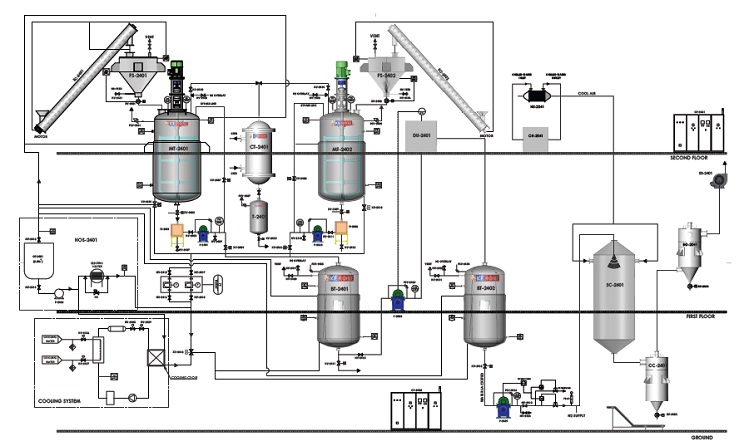

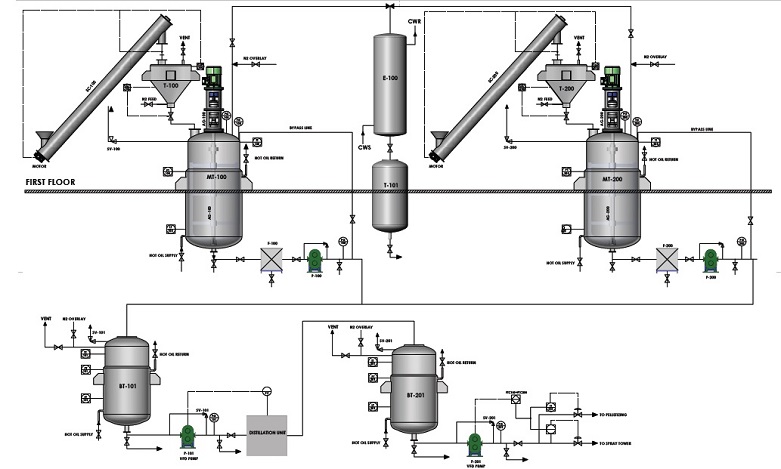

Polyethylene wax can be manufactured using either Polyethylene or from ethylene itself, this involves high pressure reaction. Our Polyethylene wax processing plant is designed to offer good agitation for breaking solids, even expose of heating,discharge of liquid wax, separations of solvent/water/oils and inline filtration for dirt for final purifiedwax. Filtration to separate dirt at 1800 cells is very important to achieve good quality Wax.

Crude wax will gradually heat treated with control temp-time profiles for separation of impurities in stages like hexane (65-70 0 cells), water (70-100 O cells) and oils (110-180 O cells) to get pure wax liquid and after natural/force cooling to solidify.

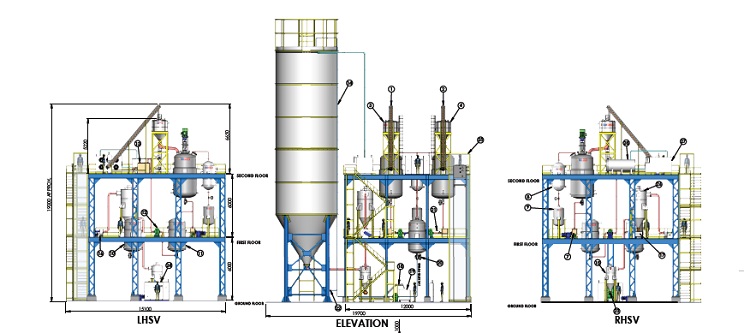

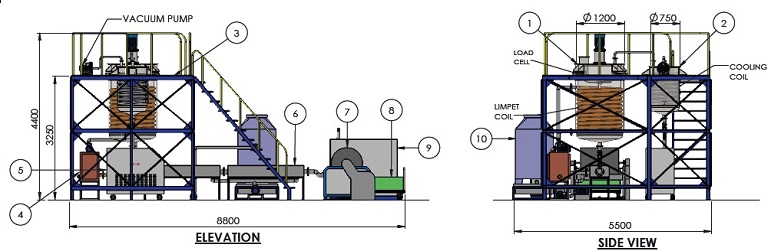

Components of Polyethylene wax processing plant:- Agitation Tank with limped OR Jacketed Heating (Design temp 200-180 deg cells).

- Condensate tank with Cooling coils & water ring type Vacuum Pump.

- Thermic Fluid HCS System (Electric).

- FBV with inline Filter (180 deg cells).

- Floor Slat Conveyor with Cooling Chamber.

- Wax landing SS Trays.

- PLS Control Panel.

- Platform, structure, ladder, railing and piping etc.

- Stainless steel chamber

- Precise control system

- Easy to operate

- Varied range of temperature setting

- Large capacity chambers