Reverse Roll Coating Machine

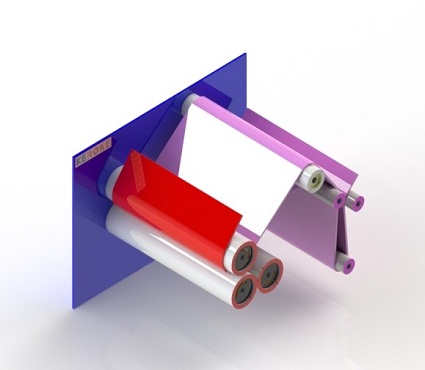

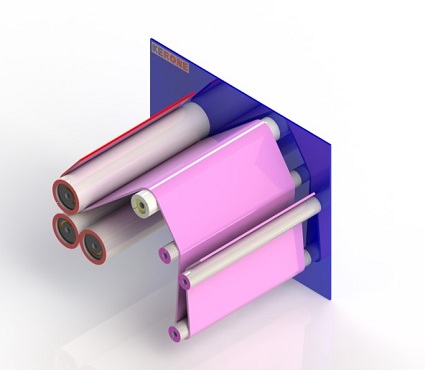

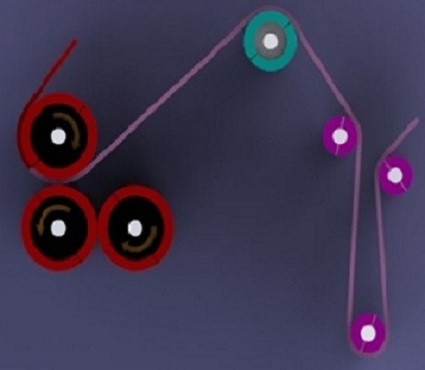

Reverse roll coating is a roll-to-roll coating strategy for wet coatings. It is separated from other roll coating systems by having two reverse-running nips. The metering roll and the applicator roll turn in inverse directions with the rate contrast of 50% to 150%, with an exact crevice between them. The surface of the applicator roll is stacked with an overabundance of coating before the metering nip, so its surface rises up out of the metering nip with an exact thickness of coating equivalent to the crevice.

In reverse roll coating, the coating material is measured onto the applicator roller by exactness setting of the hole between the upper metering roller and the application roller underneath it. The coating is "wiped" off the application roller by the substrate as it goes around the bolster roller at the base. The chart delineates a 3-roll reverse roll coating process, despite the fact that 4-roll forms are normal.

We at KERONE are having 48+ years experience in designing and manufacturing various types of specialized coating and impregnation plants for various industrial processing needs of our clients. We are having immense experience in designing and manufacturing of Reverse Roll coating machine that can best fit for the size and various processing requirements of the client’s business. The Reverse Roll coating machines manufactured by KERONE are made with high quality internal and external material by taking discreet efforts for the perfect coat and uniform heat distribution.