Sulphur Melting and Granule Plant

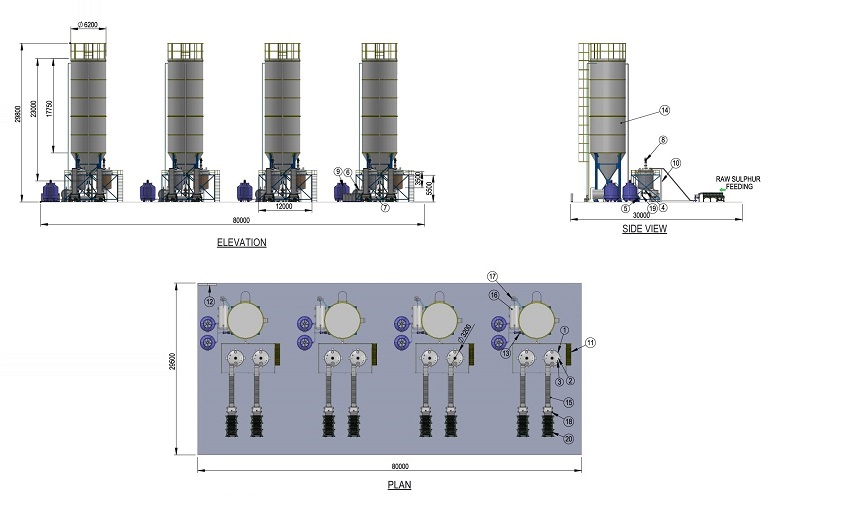

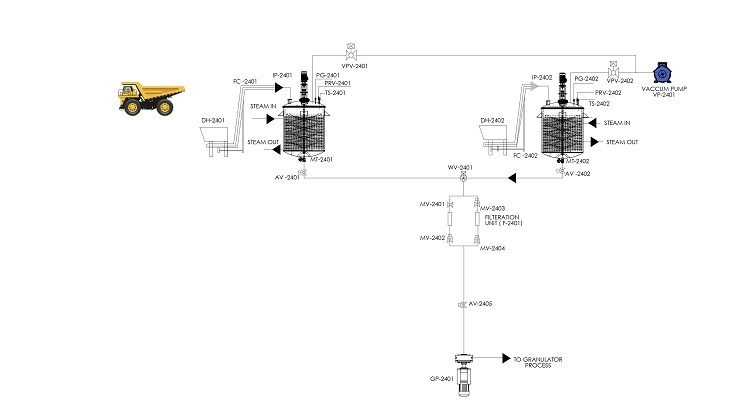

The typical KERONE sulphur melting and filtration process starts in the solid sulphur handling section, where solid sulphur gets loaded on a conveyor belt and gets neutralised by adding lime.

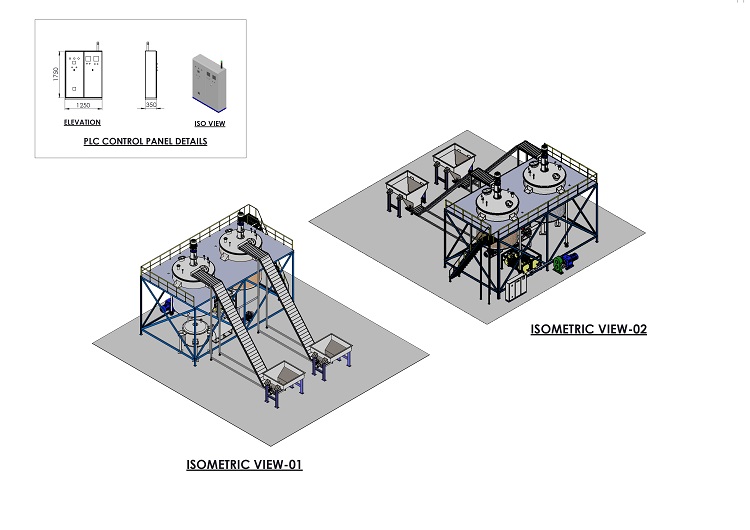

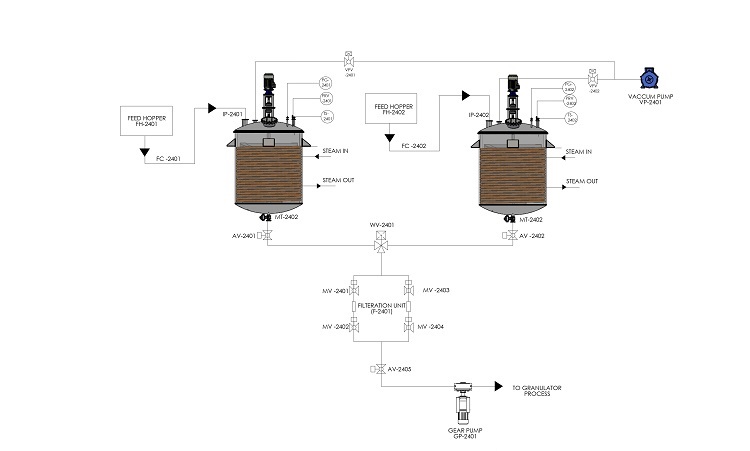

Using the conveyor belt the solid sulphur is transported to the liquid sulphur melting tank, where the sulphur is heated until its melting point to form liquid sulphur.

Where once the Liquid Sulphur flow from the Melting tank into the dirty sulphur tank from where it's pumped to the liquid sulphur filter. Inside the liquid sulphur filter, solid particles are removed from the liquid sulphur. Additionally, a liquid sulphur polishing filter is installed when the liquid sulphur filter to remove even finer particles and to act as a safety filter.

The now clean liquid sulphur is stored in the liquid sulphur storage tank from where it can be used by other processes requiring clean liquid sulphur.

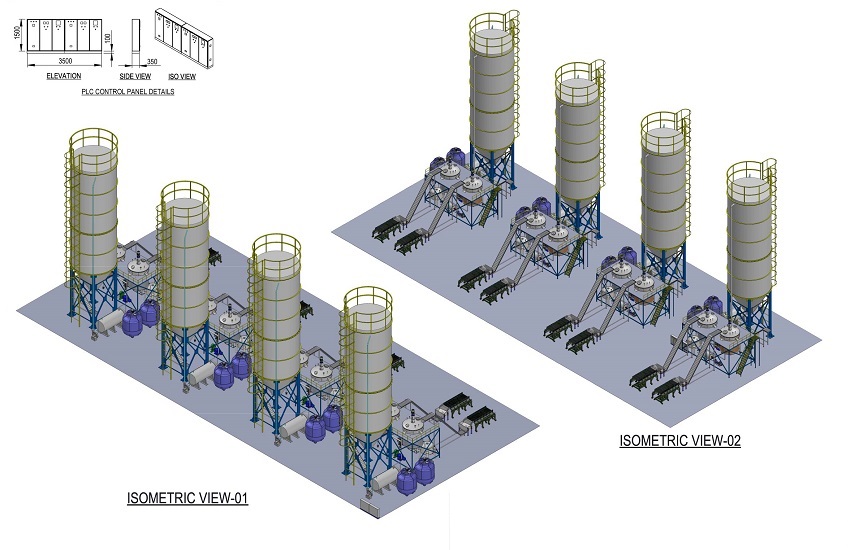

KERONE has targeted its activities on the design and manufacturing of liquid sulphur melting and purification plants. We engineer complete Sulphur melting and filtration systems to the strictest production and environmental needs, with a typical key project covering the whole process from the Solid Sulphur Feeding conveyors, up to the clean sulphur storage tank.

Our activities vary from the FEED (front-end engineering design) to the production and start-up of the plant. KERONE delivers key solutions for sulphur melting and purification, including utility equipment and control systems.