Spray Dryers for Fruit Powder

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

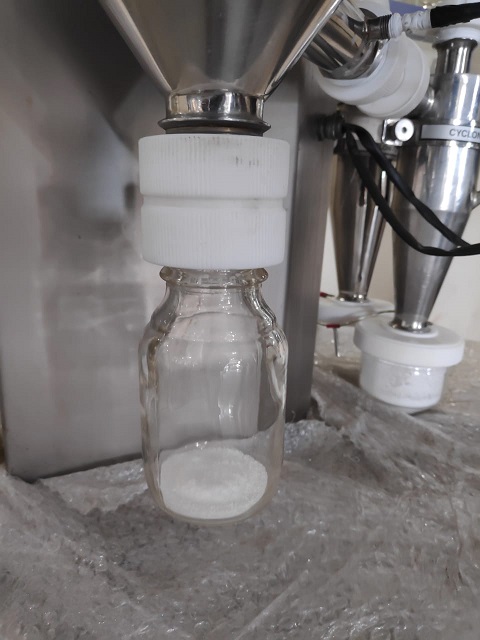

For the manufacturing of fruit powder, Kerone is a top provider of spray dryers to the food and beverage sector. At Kerone, we manufacture spray dryers that range in complexity from simple to extremely complicated, depending on the fluid or slurries being processed. The atomization, airstream pattern, air heating systems/technique, separation and collecting unit, and other design elements differ. Spray dryers are primarily made up of a drying chamber, an atomization and dispersion system for supplying fluid into the chamber in tiny droplets, an air heating system, and a separating unit to gather the dried output.

Spray dryers are machines that are commonly used in the food industry to convert liquid or semi-liquid materials into a dry powder form. In the context of fruit powders, spray dryers are used to produce powders made from fruit juice, puree, or concentrate.

The process of spray drying involves first creating a liquid mixture of the fruit material, which is then sprayed into a heated chamber using a nozzle. The heat in the chamber causes the water in the mixture to evaporate rapidly, leaving behind a fine, dry powder.

Spray dryers are popular for producing fruit powders because they allow for precise control over the size and shape of the powder particles, as well as the moisture content of the final product. This makes it possible to create powders with consistent quality and texture, which can be used in a variety of food products, such as baked goods, confectioneries, and beverages. Additionally, fruit powders produced by spray drying have a longer shelf life and can be stored more easily than liquid or puree forms of the fruit.

Application- Chemical Industry

- Food Industry

- Pharma Industry

- Effluent treatment

- Flavoring

- Nutritional supplements

- Food coloring

- Seasoning blends

- Baby food

- Construction of equipment to ensure high standards of sanitation;

- Low temperature drying that preserves the attributes of the original fruits.

- To ensure easy operation, the system is fully autonomous, small, and energy-efficient.

- The plant's footprint is planned in accordance with the customer's land availability.

- Complete sanitary design system

Q1. What is meant by fruit powder spray drying?

It transforms fruit pulp or puree into a fine powder using controlled hot air drying.

Q2. Does this method retain natural fruit color?Yes, optimized temperatures maintain color, flavor, and nutritional value.

Q3. Which fruit powders can be produced?Mango, strawberry, apple, banana, papaya, and berry powders are commonly made.

Q4. Is the powder free-flowing and easy to store?Yes, spray drying reduces moisture to create a stable, storage-friendly product.

Q5. Where is fruit powder used?It is used in confectionery, instant foods, bakery blends, and health supplements.