Ready to Eat Meals Food Processing Plant / Line

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

A ready-to-eat meals food processing plant is a facility that produces pre-cooked or partially cooked meals that are packaged and ready to eat. These meals are designed to be convenient and easy to prepare, often requiring little or no additional cooking before consumption.

The process of producing ready-to-eat meals typically involves cooking, cooling, and packaging the food in a controlled environment. The meals are then stored under refrigeration or frozen until they are ready to be shipped to retailers or directly to consumers. Some examples of ready-to-eat meals include frozen dinners, pre-packaged salads, sandwiches, and snack packs. These types of meals have become increasingly popular in recent years due to their convenience and the busy lifestyles of many consumers.

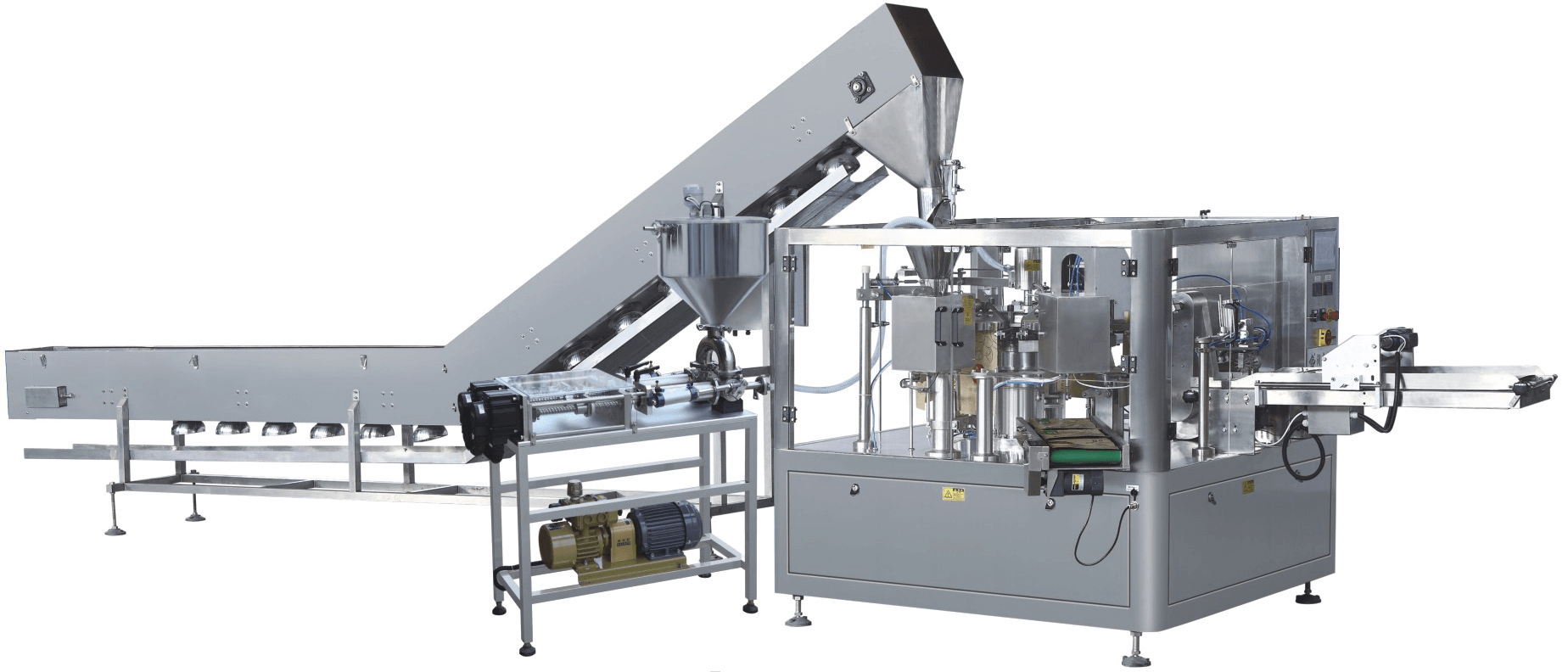

In our 48 years’ experience at Kerone we have witnessed the changes in the food processing technology and have effectively utilised the Microwave technology for various food industry processing applications. We are innovative technology partner of food processing clients, utilising microwave and IR for food processing, designing hybrid processing plants for critical application, low temperature processing. Kerone is a global manufacturer of advanced food processing systems and equipment, including solutions for the production of ready-to-eat meals. They offer solutions for heating, cooling, drying, cooking, chilling, packaging, and storage of ready-to-eat meals. Their products include cookers, chillers, and other machines for processing and packaging food products.

Ready to eat meal food machines can provide a range of benefits to food processing plants, including increased efficiency, improved food safety, and higher product quality.

Ready-to-eat meal food machines are versatile and can be used for a variety of applications in food processing plants, from cooking and cooling to packaging and portioning.

Advantages of Ready to eat Meal food machines:- Increased efficiency

- Improved food safety

- Consistency

- Reduced processing time

- Customization