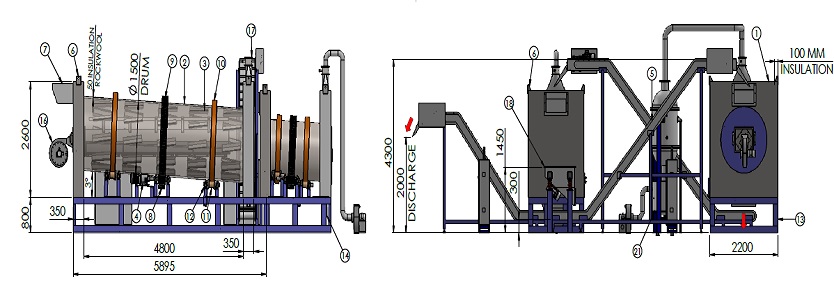

Rotary Drum Dryer with Coater

Kerone Engineering Solutions Ltd. is a leading company in the provision of advanced industrial heating, drying, and process solutions of engineering globally. Having more than 50 years of expertise, we are experts in designing, producing, and delivering custom-made, state-of-the-art systems to meet the ever-changing requirements of the industries across the globe.

We have been involved in engineering excellence, sustainability, digitalization, and technological innovation to become a reliable collaborator whose business partners are in various industries. Kerone will implement Artificial Intelligence (AI), Machine Learning (ML), and Internet of Things (IoT) technologies in our systems to ensure smarter automation, real-time monitoring, predictive maintenance, and process optimization that is data-driven, thus enabling our clients to be more productive, efficient, and reliable.

The Kerone systems are designed to meet Industry 4.0, which leverages AI-powered analytics and IoT connections to provide clients with data insights and intelligent automation to manufacture next-generation products.

Rotary drum dryer with coater is to unravel the problem of granular compound fertilizer caking and with special design, easy to moisture absorption. The equipment will use a uniform coated surface with protection film in granulate fertilizer. That is control the surface of fertilizer special situation about salt bridge and moisture condition effectively. So the machine solves the problems of caking for chemical fertilizer and organic fertilizer. Rotary drum coating machine equipment components by mixing ingredients tank, oil pump, and rotary machine. According to the necessities of the powder coating process of powder or liquid. The structure made a special design that make fertilizer uniform particles, and lead into protective film in the surface of fertilizer. The purpose of preventing agglomeration in the process of compound fertilizer is stored.

The coated fertilizer pellet into the coating machine, and atomized spray into the coated materials, along with the roller rotation and granulated fertilizer with non-uniform curve lining plate rolling, the mutual friction, extrusion, glue coating, coated material equally coated in the fertilizer particle surface gradually, complete fertilizer coating method, discharging from coating machine.

Rotary drum coating machine will use a uniform coated surface with protection film in granulate fertilizer. The result is control the surface of fertilizer special situation about salt bridge and moisture absorption effectively. Rotary drum coating machine has some special design according to the need on the internal structure that is a kind of efficient equipment for organic fertiliser and compound fertilizer equipment.