Termination Selector Guide

Fiberglass insulated lead wires externally connected to nickel pins. The connections area is electrically insulated with heavy-wall fiberglass sleeving.

Swaged-in Flexible Leads

Fiberglass insulated lead wires are internally connected to nickel pins. This design allows for great flexibility at the lead exit point of the heater.

Teflon Leads & Seal

Teflon insulated lead wires with a teflon end seal swaged into the heater sheath provides a moisture resistant design. This design requires a minimum of 1” cold section at lead exit end of heater.

Internal Thermocouple

Type J thermocouple provides integral method for temperature control. Thermocouple junction (grounded or Ungrounded) can be located at the end disc, center or lead end.

Please specify. Other thermocouple types are available.

Straight Braid Lead ProtectionStainless steel braid over fiberglass insulated lead wires exits straight from heater sheath for abrasion resistance.

3" additional lead beyond braid is standard.

Armor cable over fiberglass insulated lead wire exits straight from heater sheath for heavy duty lead protection.

3" lead beyond armor is standard. Specify galvanized or stainless steel armor when ordering.

Right Angle Armor Cable With Copper ElbowArmor cable leads extend at right angle from heater with right angle copper elbow.

3" lead beyond armor is standard. Specify:

galvanized or stainless steel armor; length of heater sheath.

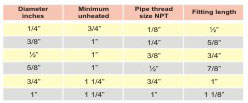

Immersion Pipe Fitting

Threaded NPT pipe fitting is silver soldered directly to heater sheath for immersion applications. Fiberglass insulated lead wires exit high temperature cement potting. 3/4” cold required before fitting.

Specify: “MS” for Stainless fitting “MB” for brass fitting

Mounting Flange

Stainless steel flange welded directly to heater sheath. Fiberglass insulated lead wires are standard. Other flange sizes and hole patterns are available upon request.

Post Terminals

Threaded stainless steel terminals are welded directly to nickel pin for rigid mount applications. Includes two (2) nuts and washers for each terminal.