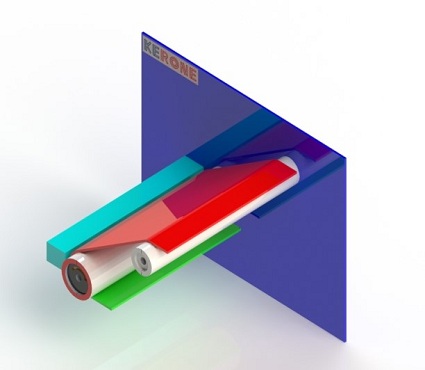

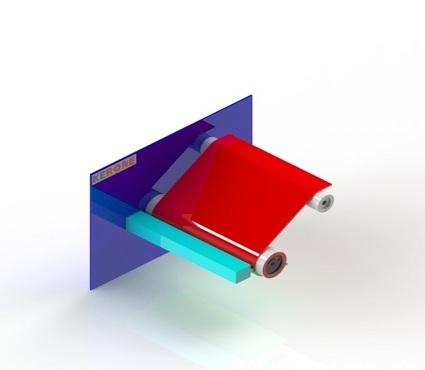

Slot Die Coating System

In the Slot Die process, the coating is pressed out by gravity or under weight through a slot and onto the substrate. In the event that the coating is 100% solids, the process is termed "Extrusion" and for this situation, the line velocity is regularly much speedier than the rate of the extrusion. This empowers coatings to be significantly more slender than the width of the slot. Slot Die Coating is a repeatable, solid coating strategy that keeps on gaining support in a mixed bag of coating.

We at KERONE are having 48+ years experience in designing and manufacturing various types of specialized coating and impregnation plants for various industrial processing needs of our clients. We are having immense experience in designing and manufacturing of Slot Die coating machine that can best fit for the size and various processing requirements of the client’s business. The Slot Die coating machines manufactured by KERONE are made with high quality internal and external material by taking discreet efforts for the perfect coat and uniform heat distribution.

Advantages- Able to Coat Organic or Inorganic Liquids on flexible or rigid substrates

- Excellent coating uniformity (typically ±3% or better)

- Capable of coating a wide range of process materials: high and low viscosity fluids

- Deposit a wide range of thicknesses

- High efficiency / high material utilization: typically 96% process material utilization

- Technology proven scalable from small R&D to large panel, high volume/mass production

- Highly reliable and robust process

- High throughput (low TACT) processing