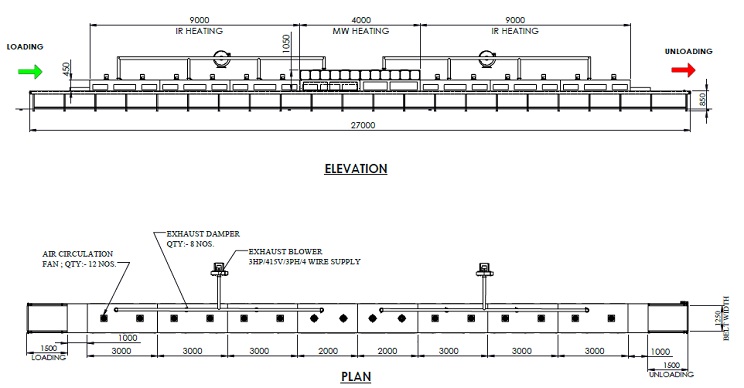

Infrared Food Processing / Production Line

Infrared based food processing systems utilise the infrared radiation from electromagnetic spectrum that penetrates through food and results in vibration and revolution of molecules, stage when the molecules returns into the normal state, it produced the heat. IR radiation are superior than the conventional heating techniques as the heat is generated at the surface of food material and transfer of heat fast and direct, no heating of surrounding air. The IR heating depends on

- Surface property of material

- Type of radiation

- Shape of emitter and receiver

Infrared heating technology is suitable of various food processing techniques such as drying, baking and roasting, blanching, pasteurization and sterilization.

Infrared Food drying:Application of infrared have become popular in Food drying application due to its distinctive properties of heating and drying at the surface of food, at no time. Food dried using IR is having greater rehydrating property compared to one dried using conventional drying systems. Plethora of advantages that IR food drying offers are reduced drying time, alternate energy source, increased energy efficiency, constant temperature in the product while drying, better-quality finished products, a reduced necessity for air flow across the product, high degree of process control parameters, and space saving along with clean working environment.

Though Infrared offers verity of advantages over conventional drying process of foods, however it not the remedy for all problems hence as per your drying requirement, we at Kerone design the drying solution that will offer best drying practice by selecting best IR radiator type or combining conventional and IR together as hybrid system.

Infrared baking and roasting:Infrared (IR) baking and roasting process is more efficient and instantaneous compare to conventional baking ovens. High rate of heat transfer to the food surface can be comfortably achieved, without wasting any heat in oven surrounding heating, this makes IR baking process to reduce total energy consumption. IR food baking ovens can easily be controlled and selective area baking can be achieved by exposing only selected portion of food to be back to IR radiation, control heat by short start-up and shut-down times. IR baking system can significantly shorten the baking time compared to carrying out same in a conventional oven.

With IR baking thick crust formation can be achieved quickly, unlike conventional baking ovens which take larger time to achieve same. IR baking and roasting ovens with carefully selected IR booster help to achieve the desired colour and thickness without losing nutrition contains.

IR Baking ovens offer following advantages

- Short baking times.

- High thermal efficiencies.

- Good control over baking conditions.

- Rapid start-up, as it is not necessary to heat the air in the oven.

IR is advocated to be more suitable of enzyme inactivation as compared to other blanching techniques, it deactivates the enzymes as well as keep the nutrition level intact. Blanching is critical for storage of fruits and vegetables as no blanching and under-blanching may result in undesirable changes in sensory characteristics and nutritional properties.

IR based blanching process offer higher degree of blanching without changes texture, physical property and nutrient level of fruits and vegetables. IR is advantageous in comparison to other heating techniques, it offers:

- Short processing time.

- More energy efficient.

- Enhanced production quality.

- Lower floor space required.

The process if pasteurisation is done to remove pathogenic bacteria and prevent the disease and spoilage due to bacteria to improve food quality. At Kerone, we strive hard to provide best solution that save time, energy and become more profitable, hence we design and build IR pasteurisation system with short penetration depth which converts all heat at the surface only, and do not destroy microorganisms directly, but this is achieved by raised surface temperature. In most solid foods inner heat conduction is low and IR can therefore be used to increase the surface temperature adequate level to achieve microorganism reduction without producing significant rise in inner temperature.

Advantages that IR offer for pasteurisation process are:

- Controlled processing time.

- Efficient energy utilisation.

- Enhanced production quality.

- Lower floor space required.

- IR pasteurised foods can be sent directly to packaging

Food sterilisation process is the one in which foods are heated at a sufficiently high temperature and for a sufficiently long time to destroy microbial such as fungi, bacteria, viruses, and prions and enzyme activity. Sterilisation of foods by the application of heat can either be in sealed containers or by continuous flow technique.

We at Kerone, provide Infrared based sterilization unit for both batch type and continuous type unit for food protection. We utilise IR radiators that produce Far-IR which can radiate within the food item under processing, this results in higher temperature in very shorter duration of time, this sudden rise in temperature kill all microorganisms without affecting natural property of food product.

Advantages of IR sterilisation:

- Selective Heat Treatment

- Very low floor space required typically ¼ of space when compared to conventional system

- Ease of control by start and stop of emitter

- Lower maintenance of changing filters or emitters

- Great transfer of energy allows surfaces to be heated more quickly to overcome conduction losses

- No combustion products

- Air circulator are not required