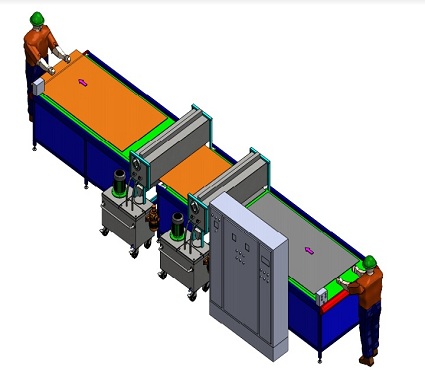

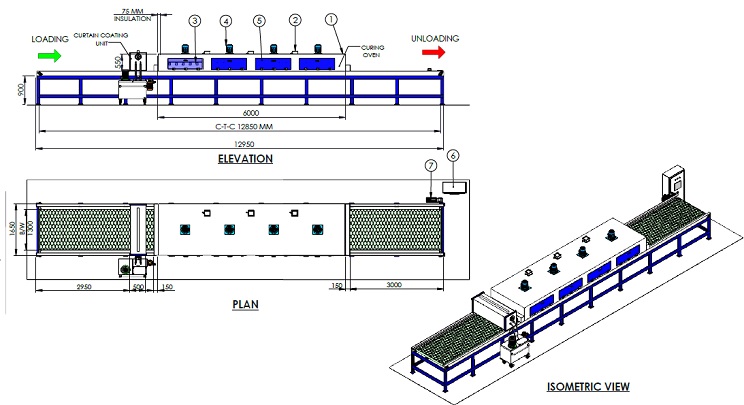

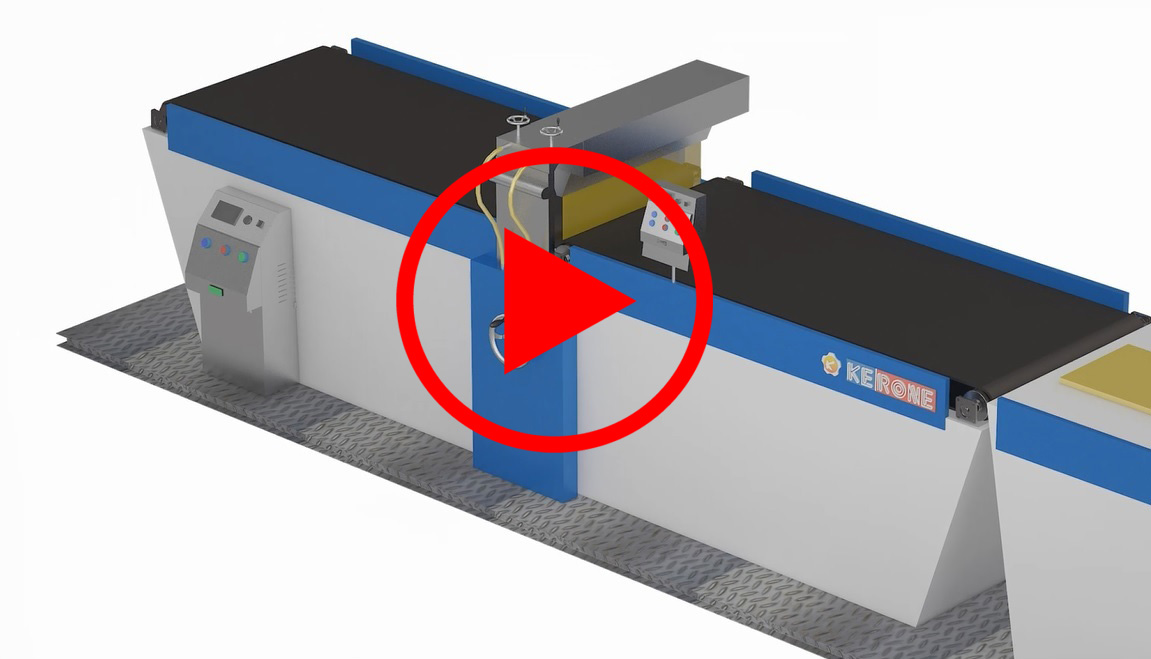

Curtain Coating Machine

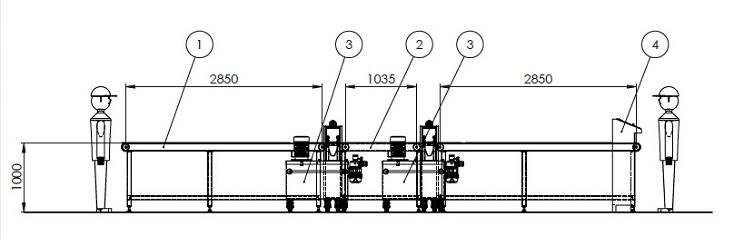

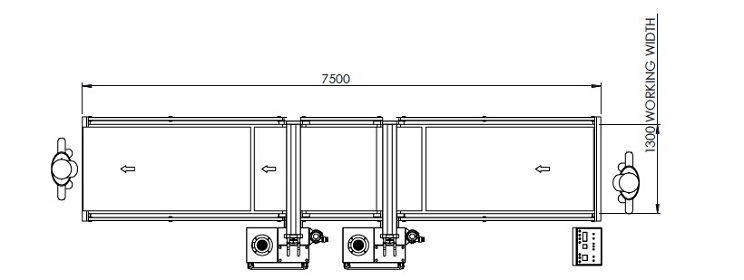

Curtain coating process creates an uninterrupted curtain of fluid that falls onto a substrate. The object to be coated, such as a door, is passed along the conveyor at a controlled and continuous speed so as to receive even coating on its upper face. The curtain is created by using a slit or die at the base of the holding tank, allowing the liquid to fall upon the substrate. For optimum usage, the excess liquid can also be collected in a catch pan and be directed towards the holding tank to reuse for the same process.

The most important aspect to be taken care of in curtain coating is the flow rate. The flow rate must be adjusted depending on the thickness of the fluid as the minimum flow rate differs among various fluids.

We at KERONE are having 48+ years experience in designing and manufacturing various types of specialized coating and impregnation plants for various industrial processing needs of our clients. We are having immense experience in designing and manufacturing of Curtain coating machine that can best fit for the size and various processing requirements of the client’s business. The Curtain coating machines manufactured by KERONE are made with high quality internal and external material by taking discreet efforts for the perfect coat and uniform heat distribution.

Uses- Promotional, opening price-point and moderate market levels.

- Cookware: Interiors and exteriors.

- Bakeware

- Small electrics.

- Speed: This system can coat from 3,000 to 4,000 pieces per hour.

- Minimum personnel required.

- Virtually no waste: Since the small amount of unused coating is cycled back into the system, this method wastes less coating than any other.

- Aesthetics: The only non-spray process that imparts a smooth, glossy finish, with no track marks.

- Flexibility: Disks can be as thin or as thick as specifications require.