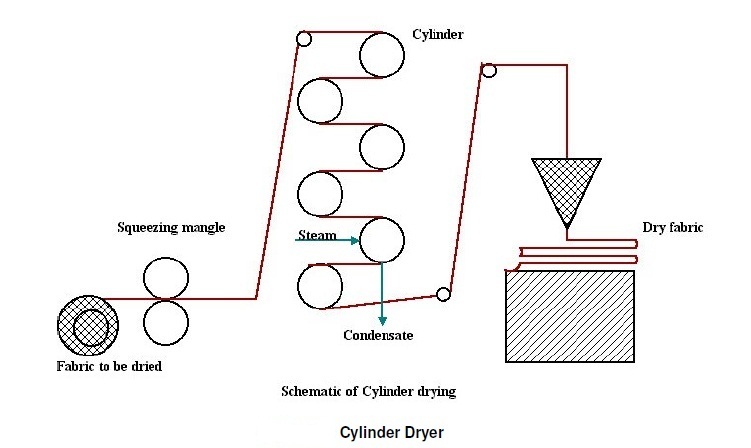

Contact Drying- Steam Cylinders/Cans

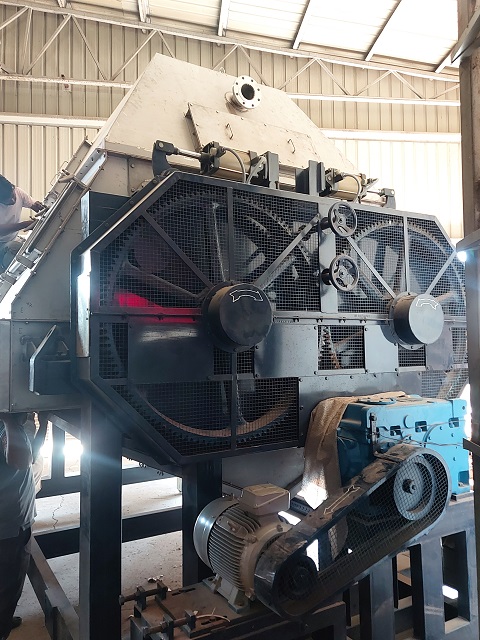

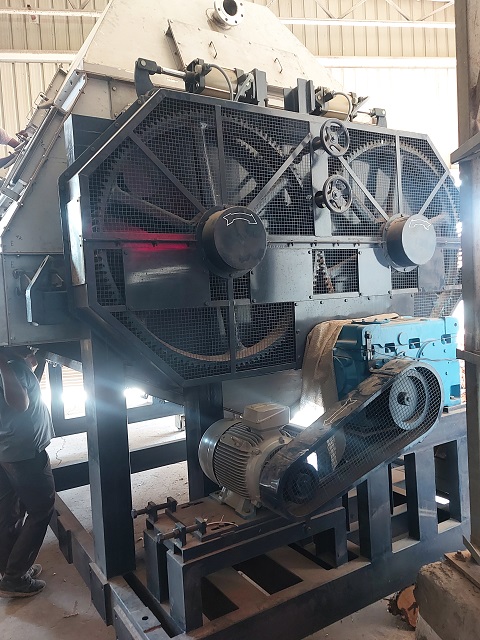

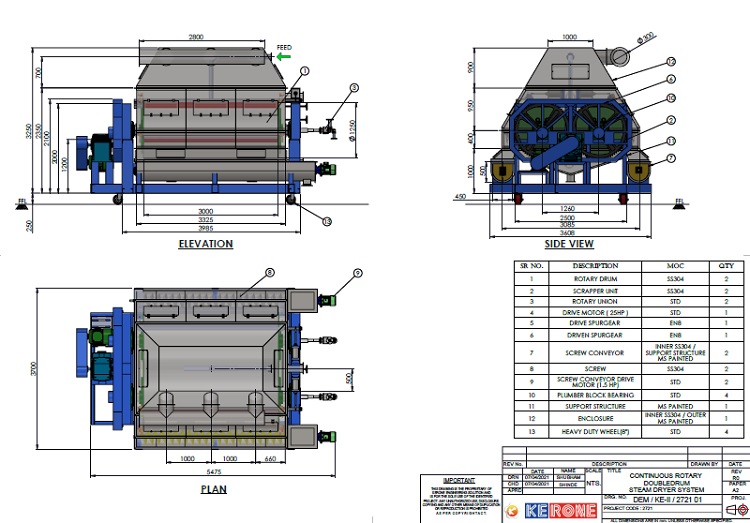

KERONE is having over 48 years experience in designing and manufacturing of various type of Contact Drying- Steam Cylinders/Cans. Our expertise with dryers and drying application, Contact Drying- Steam Cylinders/Cans the simplest and cheapest mode of drying fabrics.

Contact Drying- Steam Cylinders/Cans are primarily employed for transitional drying rather than final drying and for predrying prior to stentering. Fabric/drying material is passed around a series of steam heated cylinders using steam at pressures varying from 35 psi to 65 psi. Cylinders can be used to dry down a wide range of fabrics, but it does give a finish similar to an iron and is therefore unsuitable where a surface effect is present or required. In stenters, the fabric is width wise stretched for width fixation by a series of holding clips or pins mounted on a pair of endless chains.

It is common for steam cylinders to have problems such as leaks at vacuum breakers, air vents, rotating joints and steam traps. This is a direct result of the design of the heating system which relies on passing steam and condensate into and out of each cylinder via a rotating joint. When you have up to maybe 32 such cylinders in a single bank then the potential for leakage is considerable. It is therefore important to initiate a good maintenance regime. For example: periodically checking steam traps using an ultrasonic steam leak detector.

- Melts with wetting property to metal surface, can be flaked

- Closed construction available

- Minimize vapour nuisance

- Avoid dust contamination

- Maintains low RH air blanketing

- For inert gas blanketing

- For maintenance of suction conditions for purposes of operator comfort