Water vapor drastically reduces the net calorific value (NCV) of biogas, thereby affecting the energy performance of elements within which it’s used as a biofuel (engines, turbines, boilers, burners, etc.). Therefore, before utilizing biogas as energy, it’s suggested to reduce its moisture content as much as attainable by any means available.

Such moisture reduction is also necessary to prevent the accumulation of condensates within the gas line and therefore to prevent the formation of corrosive acids, similarly because the clogging of pipes. The water vapor content of the biogas is directly associated with both the operative temperature of the biogas production system and also the ambient temperature in general.

KERONE drying technology combines a cooling and condensation technique that permits an elimination efficiency of over 95th to be achieved, reckoning on the operating temperature, whereas additionally giving low operative prices.

This can include a recoverer-washer, which in addition to minimizing the energy desires of the operation, permits the biogas to be washed with its own condensates. This produces a partial reduction of the H2S and NH3 that accompany the biogas, which is why it will be considered a useful technology.

Since 1976, KERONE has been developing the biogas drying system, which offers the following benefits:

- Smaller footprint

- Enhanced evacuation of condensates

- Lower probability of freezing in pipes when operating at low temperatures

- Better heat transfer rates

- More efficient moisture and contaminant removal

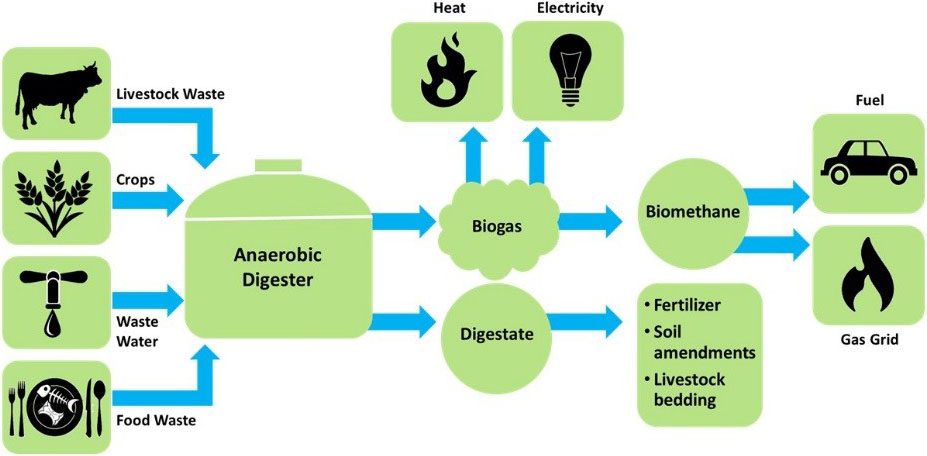

Biogas production has fully grown exponentially in recent years and also the future is promising. it’s considered the main replacement for natural gas, each as fuel for vehicles or for injection into the natural gas network.

Renewable energy, including wind power, tidal energy, solar energy, biomass, and biofuel, is striving to become the leading form of energy production.

Biogas, the gas created by the anaerobic (oxygen-free) decomposition of organic matter, is amongst the various types of energy that have their origin in biomass. It’s primarily composed of methane (CH4), which provides it the characteristic of a flammable gas.

Therefore, biogas from landfills, methanisation facilities and wastewater treatment plants (WWTPs) is a valuable material for the production of energy, biofuels and chemical products like hydrogen and methanol.

Biogas quality must be enhanced for application and use in energy production and as a raw material in the manufacturing of chemical products. Improving biogas quality involves reducing moisture content and removing all the harmful components indicated below.

Biogas drying is understood to be the partial or total removal of the moisture, mainly water vapor, in the biogas stream.

Biogas is a wet gas that needs to be dried for use in order to avoid the:

- Bad operation of CHP systems

- Formation of corrosive acids

- Plugging of the pipes by where the biogas is moved

KERONE biogas drying system is based on the combination of cooling and condensation. Sometimes works as a scrubber.

Advantages

- Produces a gas stream with low-moisture content

- High elimination efficiency

- Low power consumption

- Low maintenance cost

- Completely automated

- Robust installation

Applications

- Removing water vapor from biogas

- Partial reduction of D-type siloxanes

- Partial reduction of H2S, NH3 and hydrocarbons

- Reduced gas temperature and relative humidity

Technical features

- Modular system

- Continuous Operation

- It can reduce water vapor and, in turn, H2S, NH3, hydrocarbons and siloxanes as needed

- It can work, both in the suction line or pressure line within the biogas installation

- It may include the operation control system if requested by the client

- Automatic operation

- High biogas moisture removal efficiency

- Could have an energy recovery system or reheating

There are presently 2 basic sorts of biogas drying systems on the market, reckoning on the position of the heat exchanger unit:

- Facilities with a horizontal arrangement

- Facilities with a vertical arrangement.

We at KERONE have a team of experts to help you with your need for Bio Gas Drying Systems in various products range from our wide experience