Infrared (IR) technology is extremely energy-efficient, less water-consuming, and environmentally friendly compared to standard heating. Further, it’s also characterised by homogeneity of heating, high heat transfer rate, low heating time, low energy consumption, improved product quality, and food safety. Infrared technology is utilized in several food producing processes, like drying, boiling, heating, peeling, polyphenol recovery, freeze-drying, antioxidant recovery, microbiological inhibition, sterilization grains, bread, roasting of food, manufacture of juices, and cooking food. The energy output is enhanced utilizing a combination of microwave heating and IR heating. This combination heats food quickly and eliminates the matter of poor quality.

Heating is one of the vital thermal processes in food process and depends on the transfer of heat by conductivity, convection, and radiation. The goal of heating food is to extend its time period. Traditional heating is either by burning fuel or by utilizing electrical source. Heat is transferred from the outside surface to the surface of the food through convection and conductivity and also the temperature of the surface of the food will increase even a lot of until the heat reaches through the conductivity into the food. Once the temperature increases more, it causes physical and chemical changes of the heated substance.

The impact of IR radiation on optical and physical properties of food materials is crucial for the design of an infrared heating plant and improvement of a thermal method of food components. The infrared spectra of such mixtures originate with the mechanical vibrations of molecules or specific molecular aggregates within a very advanced phenomenon in overlapping. once radiant electromagnetic energy impinges upon a food surface, it may induce changes within the electronic, vibrational, and rotational states of atoms and molecules.

APPLICATIONS OF IR RADIATIONS IN FOOD PROCESSINGARE MAINLY IN THE FOLLOWING AREAS:

- Pasteurization,

- Baking, cooking, blanching and roasting,

- Drying and dehydration

1. PASTEURIZATION

Applying IR heating for surface pasteurization purposes has the potential to become a common industrial practice. Exposing a food product to an IR heating source results in an increase in the surface temperature, and the heat is conducted to the interior by conduction. Because food products have lower thermal conductivity, the rate of heat transfer through the food products is rather slow. Hence, an intense heat might accumulate on the surface, causing the surface temperature to increase rapidly. If the IR exposure time is properly controlled, the surface temperature can be preferentially raised to a degree sufficient to inactivate target pathogenic microorganism without substantially increasing the interior temperature.

2. BAKING, COOKING, BLANCHING, AND ROASTING

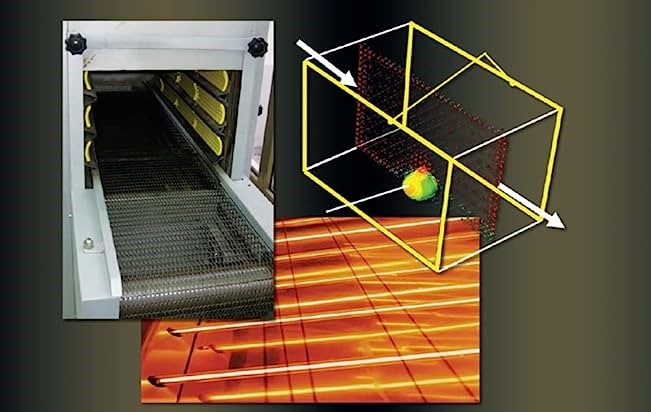

As an industrial process, IR heating, using IR ovens, and many examples of baking, cooking, blanching, and roasting using IR energy can be found. IR Dryers use quartz-tungsten tubes emitting radiation of peak wavelength of 1.2 µm to bake biscuits, and it was found that a wide range of biscuit products (crackers, semisweet, and short dough types) could be baked using IR heating in approximately half the time required in a conventional oven.

3. DRYING AND DEHYDRATION

Infrared heating provides an imperative place in drying technology and extensive research work has been conducted in this area. Most dried vegetable products are prepared conventionally using a hot-air dryer. However, this method is inappropriate when dried vegetables are used as ingredients of instant foods because of low rehydration rate of the vegetables. Freeze-drying technique is a competitive alternative; however, it is comparatively expensive.

IR radiation contains a poor penetration capability. However, the surface temperature of food materials increases quickly and heat is transferred within food materials by thermal conductivity. Typical thermal conductivities of solid foods are much less than liquid foods. Convective heat transfer to occur within liquid foods below IR heating will contribute to a rise within the morbidity of microbes.

The development and implementation of IR technologies within the food and agricultural sectors as different and sustainable ways can profit the surroundings and reduce energy and water use. Overall, efficient IR processes having environmental and economic advantages as compared to standard thermal processes is achieved by precise process management and well-designed equipment and processing system. the requirement for improved product quality, safety, and energy and process efficiency are expected to drive the industrialisation of IR technologies for food and agricultural processing.

We at KERONE have a team of experts to help you with your need for Infrared Heating in various products range from our wide experience.