Microwave energy has very successful application in the field of food processing particularly for food drying to preserve the quality of the precious food materials. Various food materials dried using microwave energy was extensively reviewed. Microwave drying appears to be a viable drying method for the rapid drying of food materials. It was noticed that at the higher microwave output power considerably lower drying time took place. The application of pulsed microwave energy was found more efficient than the continuous application. The microwave-vacuum drying could reduce drying time of vegetable leaves by around 80-90%, compared with the hot air drying. Microwave drying maintained a good green color close to that of the original fresh green leaves with surface sterilization in most of the vegetables. The microwave heating of vegetable seed reduces the moisture content and anti-nutritional factor with maintaining the natural color of the valuable seed.

Drying is the oldest and traditional methods of food preservation and is the most widely used technique of preservation, which converts the food into light weight, easily transportable and storable product. Although the origin of drying goes back to antiquity, there is a constant interest and technological improvements in the process of drying keeping this mode of preservation still as new. The specific objective of drying is to remove moisture as quickly as possible at a temperature that does not seriously affect the quality of the food. Drying can be accomplished by a number of traditional and advanced techniques.

Microwave heating is based on the transformation of alternating electromagnetic field energy into thermal energy by affecting the polar molecules of a material. Many molecules in food (such as water and fat) are electric dipoles, meaning that they have a positive charge at one end and a negative charge at the other, and therefore, they rotate as they try to align themselves with the alternating electric field induced by the microwave rays. The rapid movement of the bipolar molecules creates friction and results in heat dissipation in the material exposed to the microwave radiation. Microwave heating is most efficient on water (liquid) and much less on fats and sugars which have less molecular dipole moment.

In drying of food materials, the aim is to eliminate moisture from food materials without affecting their physical and chemical structure. It is also important to preserve the food products and increase their storage stability which can be accomplished by drying. Microwave drying is a newer addition to the family of dehydration methods.

In Microwave drying tomato slice was sampled, from the starting of the drying the change in the sample weight was recorded at the time intervals of 2 minutes. The drying tests were terminated when the moisture content indicated 10%. The final moisture content of each sample was measured in order to calculate the moisture content at each weighing interval. Among several subjective quality attributes of dried tomato slices the colour is an important one which indicates the level of effects of different drying methods or conditions.

Dried fruits are widely used as components in many food formulations such as pastry, confectionery products, ice cream, frozen desserts and yogurt. Among them, dried apples are a significant raw material for many food products. The drying process was progressed through two stages, in the first stage the samples were put in a microwave oven until drying took place mainly in constant rate period; approximately 55% of the water was removed in this period. After that the forced draft oven was used until the apple samples reached the final moisture content. The second stage, the apple samples were put in forced draft oven to reach the final moisture content. For one hour or two hours the value of the drying constant increased with increased microwave output power. The change in color values was dependent on the pretreatment. The 45% sugar solution showed decrease drying rate than the other treatment. The increasing on the density power (W/g) the drying rate increased by 35%.

Many new dimensions came up in drying technology to reduce the energy utilization and operational cost. Selective and volumetric heating effects, microwaves bring new characteristics such as increased rate of drying, enhanced final product quality and improved energy consumption. Combination drying with an initial conventional drying process followed by a microwave finish or microwave vacuum process has proven to reduce drying time while improving product quality and minimizing energy requirements. However, several factors should be taken into consideration when developing drying system for the fruits and vegetables.

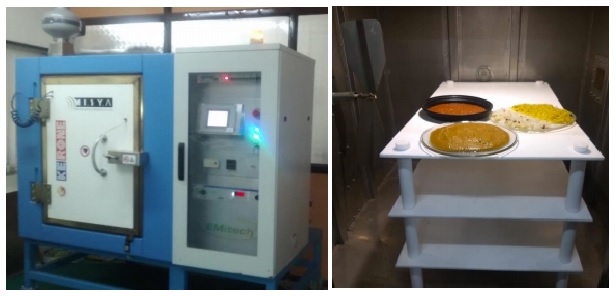

We at KERONE have a team of experts to help you with your need for Drying of Food Materials by Microwave Energy in various products range from our wide experience.