Drying of foods is an ancient practice that has been adopted to preserve foods beyond their natural period of time. The method started with the exposure of foods to the sun, to extract from them an excellent proportion of the water, so contributing for their conservation. the standard solar dying with direct exposure to the sun had several disadvantages and presently more modern ways are used, like hot air drying, spray drying, lyophilization, infrared, microwave or radiofrequency drying, osmotic dehydration or several combined processes. Many foods may be preserved through drying; however their organoleptic and nutritional properties are greatly altered as compared to the fresh counterparts.

Among the many ways used for food conservation, drying is definitely the most ancient however still much used today. It’s a method by that water is removed from the food, by vaporization or sublimation, so reducing the water available for degradation reactions of chemical, enzymatic or microbial nature. The drying rate is influenced by transfer mechanisms, like the vapor pressures of the food and of the drying air, temperature and air velocity, moisture diffusion within the product, thickness and surface exposed for drying.

The main objectives of drying include to preserve foods and increase their period of time by reducing the water content and water activity; avoid the requirement for use of refrigeration systems for transport and storage (expensive); reduce space necessities for storage and transport; diversify the provision of foods with totally different flavors and textures, so providing the consumers a good selection when buying foods.

There are several advances in drying technology in latest years, as well as pretreatments, techniques, equipment and quality of the final product. The pretreatments, for instance, are used with the aim to accelerate the drying method, enhance quality and improve the safety of foodstuffs. Besides they also help decreasing energy needs.

There are hundreds of types of dryers, based on different principles of operation.

- Solar Drying

In solar drying the energy source is the sun. Therefore it is a very cheap drying method, but on the other hand it has many drawbacks because the food is exposed to contamination sources (insects, birds and other animals) and is also strongly susceptible to weather conditions.

- Hot Air Convective

Drying the convective drying of porous media, including foods, has a pivotal role in several industrial applications. Owing to its high availability and moisture saturation capacity, the air is undoubtedly the most used drying fluid.

- Spray Drying

Spray drying is a widely used technique to convert a liquid state into a powder form. It is used for solutions or slurries that go through an atomizer or spray in order to divide the material into droplets (10-200 mm). The quality of spray-dried microcapsules is quite dependent on processing parameters of the spray dryer and properties or composition of the feed solution.

- Lyophilization

In lyophilization, also called freeze-drying or freeze dehydration, the water is first frozen and then sublimated, under special conditions of pressure and temperature. Lyophilization is slower and with higher costs, because it involves freezing, the production of vacuum and the equipment is itself expensive.

- Infrared Drying

In infrared drying, the solid food is exposed to a source of infrared heating increasing the temperature of its surface. Because most of the solids have a low thermal conductivity, the rate of heat conduction to the interior is very slow. Hence, the application of infrared radiation primarily intends the surface treatment of foods.

- Microwave Drying

This method provides a high heating rate and does not originate alterations on the surface of the food and hence no crust is formed. The industrial microwave treatment is limited due to its high cost and to the need to synchronize the generator for different foods. Thus, it is used industrially for low moisture foods, or as a final stage of the dehydration process.

- Radiofrequency

Drying the use of radiofrequency energy for dielectric heating of food materials is an important application area, which has been studied as a possible method for drying agricultural products. The radiofrequency heating addresses directly the product, so that its interior is heated faster than its surface. The water is released without overheating or dehydration of the surface. Therefore, it can be used as a complement to other drying processes, and allows reaching very low humidity levels, of the order of 1 to 2%, with minimal impact on quality. This novel drying method provides shorter time, higher energy efficiency and better product quality as compared to conventional hot air heating.

- Osmotic Dehydration

Osmotic dehydration is based on the principle that when cellular materials are immersed in a hypertonic aqueous solution, a driving force for water removal sets up because of the higher osmotic pressure of the hypertonic solution. It is generally used for partial removal of water from fruits or vegetables which are immersed in a sugar or salt solution. The food loses water to the solution but in many cases its final moisture content is not stable.

- Combined Processes

There are many conventional drying methods used in post-harvest technology including solar drying, osmotic dehydration, vacuum drying, hot-air drying, fluidized bed drying, and freeze drying. However, most of these drying techniques involve longer drying time and high amount of energy, resulting in poor quality of the dried products. It has been suggested a new way of improving the existing conventional drying processes based on self-heat recuperation technology. However this method, which focuses mainly on increasing the energy efficiency of the drying process, is complex and expensive to adapt.

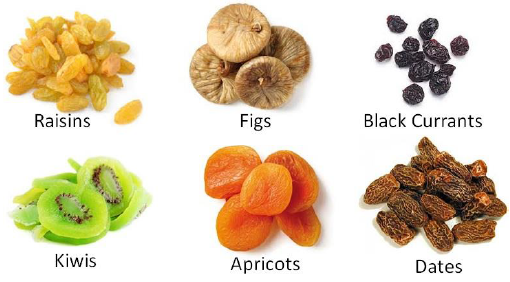

- Fruits

Many fruits have been for long dried in the sun, including grapes, figs, dates, pears, peaches and apricots. Nevertheless, the hot air for drying is also amply applied to fruits such as apple slices, apricot halves, pineapple slices or pears in halves or quarters. Other drying methods like vacuum drying or combined methods can be used to dry fruit, such as kiwi, mango and banana. The osmotic dehydration is applied to orange, pineapple, kiwi, apple, cherry, papaya, coconut, and strawberry, among many others.

In general fruits are not blanched but are sulphited by exposure to vapors resulting from the burning of sulphur, to control minimize browning reactions. Fruit purees can be drum dried to obtain powders or flakes, like in the case of banana, apricot, mango and peach. Some of these products are hygroscopic and sticky, so it is beneficial to add glucose syrup to facilitate removal of the product from the drum and its subsequent handling. For the drying of fruit juices can be used atomization or spray drying.

CONCLUSION

The drying operation may be a very ancient practice for food preservation, however rather than being abandoned presently it continues very important process of treatment for wide-ranging food products. A lot of innovation and technological advancements have led to higher drying processes, more efficient in energetic terms and allowing a much better preservation of the organoleptic and nutritional qualities. The applicability of the method to a wide range of foods, with numerous characteristics renders this operation a prominent position within the process of food industries.

We at KERONE have a team of experts to help you with your need for Drying in various products range from our wide experience.