Drying is an efficient technique for fruit storage/preservation. Drying may retain quality end product that is difficult, because all fruits are variable in structure, so, heat and mass transfer modeling (operating parameters) is a helpful technique to deal with it. This could only be done by selecting the proper sort of drying equipment and understanding the science behind the drying method as well as thermal properties of fruit. Drying method have several effects on different heat sensitive fruits elements and equipment (sensors etc.) also that result into increase in maintenance price, diffusion rate goes to critical limits etc. Because, choice of an acceptable drying technique and equipment is most significant regarding product quality and its amount. Modeling of a drying method considering different drying parameters and their effects on final quality of product and economic importance are mentioned here. we must always have information regarding the drying mechanics. So, that knowledge of heat and mass transfer method for fruit drying helps to identify best operating conditions and saves the most quantity of energy.

Food is the necessity for mankind as it provides energy, growth, and repair to the body. Fruit is an agricultural commodity and most of the agricultural commodities are seasonal. Fruits are present in bulk amount during their season, but during the offseason, this seasonal fruit is unavailable because it gets wasted due to improper storage techniques. About 40% of the fruits production in Pakistan was wasted due to improper handling and preservation techniques. Fruit production in Pakistan in 2016–17 is 5,685,000tons and 440,000tons were exported and 2,274,000tons get wasted. To make food secure one should reduce post–harvest losses. Fruits get wasted due to improper harvesting, transportation, processing, and preservation methods. Agricultural products are sometimes categorized on the basis of water contents present in them; perishable, semi–perishable and non–perishable products. For few days fruit can be save according to its shelf life (perish ability value), but after these days sensory parameters like taste, flavor, texture, color degrades and finally, fruit becomes unable to eat. In order to prolong its shelf life for months, dry it by proper means and in a hygienic environment.

Drying is a unit operation that is carried out to preserve fruit, instead of a unit process, which is a chemical process. Drying is the removal of moisture from fruit products up to a certain level and dehydration is the bone–dry condition of that product. Drying is a physical process performs to stabilize fruit as biological changes in fruit lead to deterioration. Cost of transportation decreases and handling becomes easy as its weight and volume reduces, consumption is followed with calculated rehydration.

Objectives of drying:

Drying slows down the microbial and enzymatic activity by lowering water activity. Apple has a water activity of 0.85–0.95 and drying reduces water activity to about 0.5.2 Fruits are dried due to many reasons; to consume seasonal fruits and to export these products in non–production areas of such fruits. Dried fruits enhance the taste of food products when used as food formulations in many food products such as ice creams, frozen desserts, sweets, bakery products, baby foods, jellies, crackers, horseradish, miscellaneous, and sauces etc.

Heat transfer:

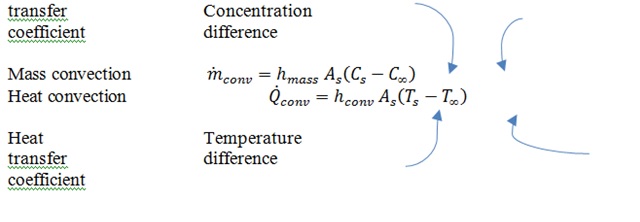

Temperature difference is the driving force for heat transfer. So, heat transfer exchanges thermal energy from high concentration to low concentration between physical systems. There are three modes of heat transfer namely, conduction, convection, and radiation.

Specific heat:

Quantity of heat required to change a unit temperature of unit mass of product, without changing in its original state.

Thermal conductivity:

Quantity of heat is conducted through per unit thickness, per unit time of the product, if two materials having a unit temperature difference.

Thermal diffusivity:

Ratio of thermal conductivity to specific heat and density.

Mass transfer:

Mass transfer is the movement of chemical species from high concentration region to low concentration region and the presence of these two regions are necessary, but fluid flow moves from one location to another and occurs on a macroscopic level

Drying process:

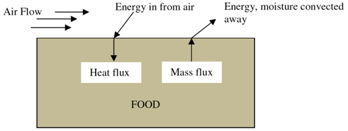

Drying is a coupled heat and mass transfer mechanism. There are different types of drying units/machinery used in this modern era. Food Engineers are working very hard to develop more efficient methods for drying of perishable agricultural products that least alter its quality.

Fruit in its biological structure is variable and complex so every fruit needs a different model to dry it by retaining quality, which is challenging. So, modeling and simulation is a useful technique to deal with it. Mathematical model based on heat and mass transfer is used to study the behaviour of drying operation.

Fruits due to high water content and heat sensitive compounds in it are tough to dry, by maintaining quality. Understanding heat and mass transfer process and its parameters are mandatory for the drying processes, which minimally have an effect on the sensory and different quality parameters of edible fruit. Calculations for heat and mass transfer greatly help to optimize the efficiency of drying unit, drying rate and as well as reduces energy consumption, it additionally helps to identify the most appropriate operating conditions.

We at KERONE have a team of experts to help you with your need for Heat Transfer in various products range from our wide experience.