There’s water within the air all around us. The moisture level in air changes because the temperature changes. For instance, cold winter air may feel drying to our skin, but a hot, humid day will produce moisture in all types of unassuming places. Your hair could show signs of unruliness on a hot day because of the increased moisture within the air. However what happens when this moisture builds up and your air compressor is filled with water.

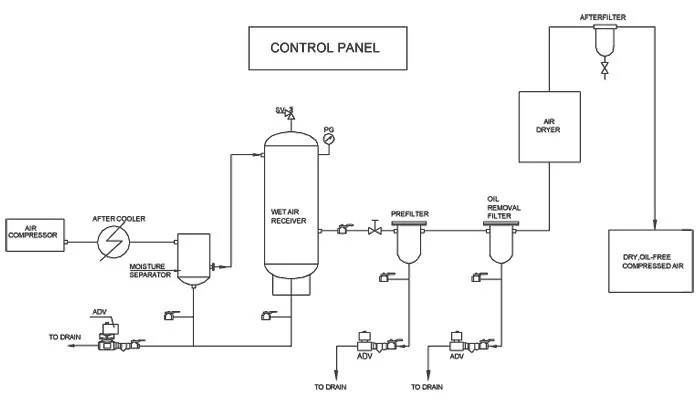

Pressurized air desires some kind of system or device to remove its naturally occurring moisture. Many choices exist to remove water from your air compressor, which may be as easy as a drain valve on the tank or as advanced as a four-stage air drying system. You will be utilizing compressed air for purposes that need moisture-free output air. In this case, any existence of moisture can negatively impact your operations.

There are applications that may tolerate a low moisture content and won’t require an elaborate air-drying setup. Either way, air compressor moisture in your tank and lines isn’t ideal, thus drying the air and releasing the water is totally necessary in some types.

For a compressor that delivers twenty liters of air per second, it also provides twenty four liters of water each day. Most of that water has to be removed, and it’s usually done in many stages. For instance, an industrial compressor that produces about twenty four liters of water each day can move the wet and hot compressed air to an after cooler that removes fifteen liters, then to a refrigerated air drier, that removes another seven liters. There is also another stage with a desiccant air drier for the driest air achievable.

Air compressors are used for a large range of applications, therefore there isn’t one good solution to each dry compressed air application. Cooler air holds less water, thus it uses several systems to cool down the compressed air. This permits water to drop out of the air, so it can be collected and drained.

Common practices to remove moisture from compressed air include:

- Draining the tank

- Using a water trap and filter regulator

- Using a refrigerated air dryer

- Using a desiccant air dryer

- Using a deliquescent air dryer

- Through piping system air drying

- With the storage tank cooling method

- Through absorption drying

Even when you work indoors, there is always a level of moisture present in the air around you. Luckily, there are several steps you can take to minimize unnecessary moisture in the air:

- Ensure adequate ventilation

- Use fans

- Fix leaks and structural issues

- Invest in a dehumidifier

- Eliminate standing water

- Clean your air conditioning filters

- Install insulation

- Use a larger air compressor

- Check the weather and plan ahead

- Use and maintain compressor air filters

- Drain your air compressor regularly

- Schedule preventive maintenance checkups

- Replace your air compressor when necessary