Metal-organic frameworks (MOFs) can be used in a variety of scientific and technological domains because they are created when organic ligands, acting as linkers, and metal ions, acting as nodes, form chemical bonds. These bonds result in the creation of periodic network crystalline structures with high porosities and large surface areas. In the field of chemical sciences, absorbent materials, zeolites, and MOFs have garnered considerable attention lately for a range of uses, such as gas storage, energy, and sensing. The intriguing feature of MOFs is their porosity nature, which allows receiver particles to diffuse throughout a mass structure. The arrangement and dimensions of pores provide visitors with a selection of arrangement and dimensions.

Because of their versatile nature, MOFs can be used to create a wide range of things with unique characteristics. They have a very high porosity, a sizable internal surface area, crystallinity, structural adaptability, diversity of functions, and flexibility. MOFs are a real competitor to traditional permeable materials like activated carbons and zeolites because of their broad interior surface area (usually 500–7000 m2/g), structural flexibility, adjustable porosity, changeable organic functionality, and physical/thermal stability.

Since MOFs are hollow, their interior surface areas are extraordinarily vast. The physicochemical qualities of the elements determine the interaction impact of structures and arrangements. MOFs are visually appealing examples of how a hollow-structured material’s unique design may provide a wide range of beneficial characteristics.

Classification of Metal–Organic Frameworks

A diverse range of scientific fields have shown considerable interest in Metal-Organic Frameworks (MOFs), a family of crystalline materials possessing distinctive features that are both adaptable and fast growing. MOFs are extremely porous three-dimensional structures made of coordinated metal nodes or clusters with organic ligands. MOFs are categorized according to one system based on the metal centers of the compounds; trivalent metals like Fe and Al contribute to more unusual structures, whereas divalent metals like Zn, Cu, and Mg are often utilized. A further categorization pertains to the characteristics of the organic ligands, which can vary in complexity from basic carboxylates to intricate functionalities that impact the stability and porosity of the framework. Moreover, MOFs may be divided into groups according to the uses they have, including medication delivery, gas storage, catalysis, and sensing. A wide range of applications, which makes them a potential class of materials for tackling issues in healthcare, the environment, and energy. The categorization of MOFs is expected to change as this field of study progresses, taking into account fresh knowledge about the compounds’ production, characteristics, and uses.

Nomenclature of Metal–Organic Frameworks

A family of crystalline materials known as Metal-Organic Frameworks (MOFs) are distinguished by a three-dimensional network structure made up of metal ions or clusters arranged in concert with organic ligands. The structure of the framework is reflected in the methodical manner in which MOFs are named. Usually, the name of the organic linker comes first, then the name of the metal.

Roman numerals enclosed in parenthesis are used to denote the metal’s oxidation state when identifying the component. For instance, the Roman number II is used to indicate that the metal is in the +2 oxidation state. The correct Roman numeral is used if the metal has more than one oxidation state. The organic ligand’s name, which is frequently formed from the ligand’s name, comes after the metal name.

Application of MOFs

Because of its special structural characteristics, Metal–Organic Frameworks (MOFs) have become a flexible and promising material with a wide variety of applications. The storage and separation of gases is one such use. MOFs are excellent options for adsorbing and storing gasses like hydrogen and methane for renewable energy applications because of their large surface areas and adjustable pore diameters. Furthermore, MOFs have demonstrated significant promise in catalysis, acting as effective catalysts for a range of chemical processes. Catalytic sites can be hosted by their porous architecture, improving selectivity and reaction rates. MOFs are becoming more and more popular in medication delivery systems. Drugs can be encapsulated and protected by the porous frameworks, limiting adverse effects and enabling controlled release and targeted delivery to certain regions.

In addition, MOFs have shown effective in tackling environmental issues by utilizing adsorption techniques to remove and capture contaminants from water and air. MOFs may be customized because of their tunable nature, which makes them useful in sensing technologies that detect gasses or biomolecules. The uses of MOFs in a variety of industries, from energy storage to biological applications and environmental remediation, are anticipated to grow as we learn more about and comprehend their characteristics.

Future Perspectives

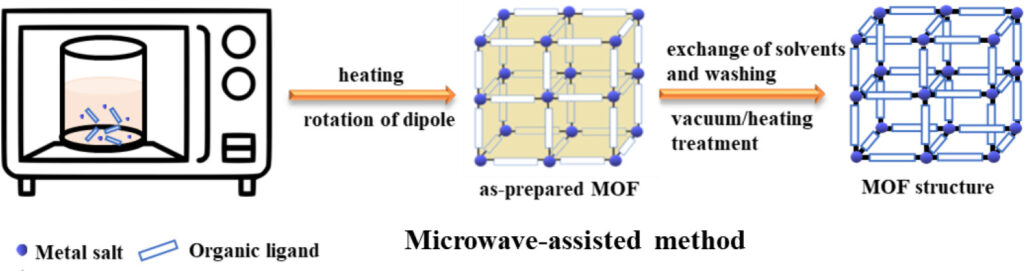

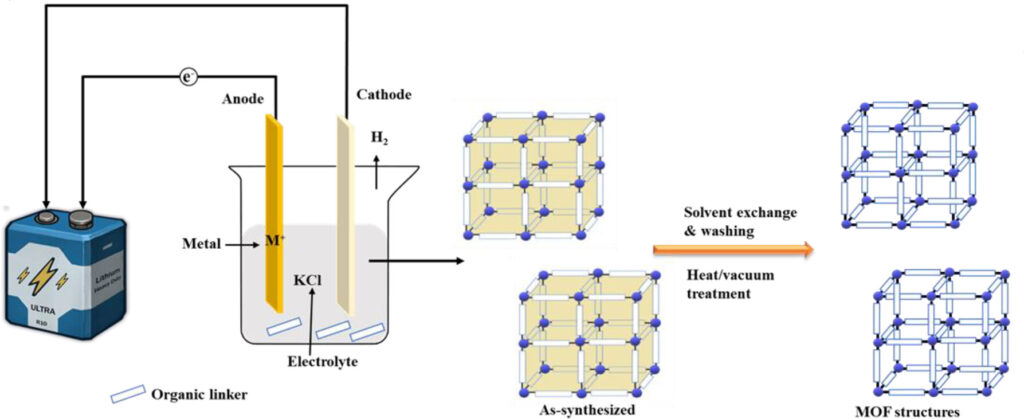

In terms of future development and innovation, the field of MOFs is quite promising. Research is now being done on creating new synthetic methods, improving MOF stability, and investigating new uses in modern industries including environmental remediation, sensing, and energy storage. Researchers from a variety of fields, such as engineering, chemistry, and materials science, will probably work together to develop new MOFs with hither to unheard-of features and capabilities. Furthermore, new possibilities for multifunctional systems and devices may arise from the integration of MOFs with other modern and advanced materials and technologies. Because of their adaptability and versatility, MOFs will be crucial in tackling today’s serious global issues and advancing several scientific and technical fields in the years to come.

We at KERONE have a team of experts to help you with your need for Metal Organic Framework in various products range from our wide experience. We manufacture and supply different industrial machinery and industrial equipment.