Heat transfer occurs through one of 3 methods, Conduction, Convection, and Radiation. Foods and biological materials are heated primarily to extend their shelf life or to enhance taste. In conventional heating, which is achieved by combustion of fuels or by an electric resistive heater, heat is generated outside of the object to be heated and is conveyed to the material by convection of hot air or by thermal conduction. By exposing an object to Infrared (IR) radiation (wavelength of 0.78 to 1000 μm), the heat energy generated can be absorbed by food materials ready to be consumed in comparatively less time and better quality. Certain characteristics of IR heating have lately increased its demand gaining more popularity such as listed below:

- Reduced Heating time

- Efficiency

- Uniform heating

- Reduced quality losses

- Higher thermal efficiency

- Faster Heating Rate

- Absence of solute migration in food material

- Compact equipment

- Significant energy saving

Combinations of IR heating with microwave heating and other common conductive and convective modes of heating have been gaining momentum because of increased energy throughput. Further in this article, aspects of IR heating and presents a theoretical basis for IR heat processing of food materials and the interaction of IR radiation with food components are explained.

Interaction of IR radiation with food components:

The effect of IR radiation on optical and physical properties of food materials is crucial for the design of an infrared heating system and optimization of a thermal process of food components. The infrared spectra of such mixtures originate with the mechanical vibrations of molecules thus processing the food and bringing out the best end results.

When radiant electromagnetic energy impinges upon a food surface, it may induce changes in the electronic, vibrational, and rotational states of atoms and molecules. As food is exposed to infrared radiation, the radiation is absorbed, reflected, or scattered. Absorption intensifies at different wavelengths of different food components. The food processing systems should be accustomed to various food substances and their ability to absorb heat at different wavelengths

Interactions of light with food material and the crucial optical principles are divided into three main types for better understanding, such as:

- Regular reflection (takes place at the surface of a material)

- Body reflection (light enters the material, diffuses due to light scattering, and undergoes some absorption)

- Light scattering (leaves the material close to where it enters)

Regular reflection produces only the gloss or shine of polished surfaces, whereas body reflection produces the colors and patterns that constitute most of the information obtained visually. For materials with a rough surface, both regular and body reflection can be observed. Most organic materials reflect 4% of the total reflection producing a shine of polished surfaces. The rest of the reflection occurs where radiation enters the food material and scatters, producing different color and patterns. It was also observed that as the thickness of the layer increases, a simultaneous decrease in transmittance and increase in reflection occurs.

Applications of IR heating in food processing operations:

The application of infrared radiation to food processing has gained momentum due to its inherent advantages over the conventional heating systems. IR radiation has been widely applied to various thermal processing operations in the food industry such as –

- Drying

- Baking

- Roasting

- Blanching

- Pasteurization

- Sterilization

Sources of IR heating:

Two conventional types of infrared radiators used for process heating are:

- Electric heaters

- Gas‐fired heaters

These 2 types of IR heaters generally fit various temperature ranges. IR temperatures are typically used in the range of 650 to 1200 °C to prevent charring of products. The capital cost of gas heaters is higher, while the operating cost is cheaper than that of electric infrared systems. Electrical infrared heaters are popular because of installation controllability, ability to produce prompt heating rate, and cleaner form of heat. In general, the operating efficiency of an electric IR heater ranges from 40% to 70%, while that of gas‐fired IR heaters ranges from 30% to 50%

Quality and sensory changes by IR heating:

It is crucial and beneficial to investigate the quality and sensory changes occurring during IR heat treatment for commercial success. KERONE has studied the quality and sensory changes of food materials during IR heating after a detailed research. (Refer the R&D Reports to know more)

It was observed that application of Infrared Heating on food items results into a better product than applying convections heat. The food IR rays penetrate inside the food item thus destroying the inhabiting pathogens inside as well as on the surface of the food product without any change in the quality attributes of foods, such as vitamins, proteins, and antioxidant activities. The research suggested that 3 to 4 minute of infrared heat treatment was adequate for commercially acceptable products with the same nutrients and visibly healthier.

Conclusion:

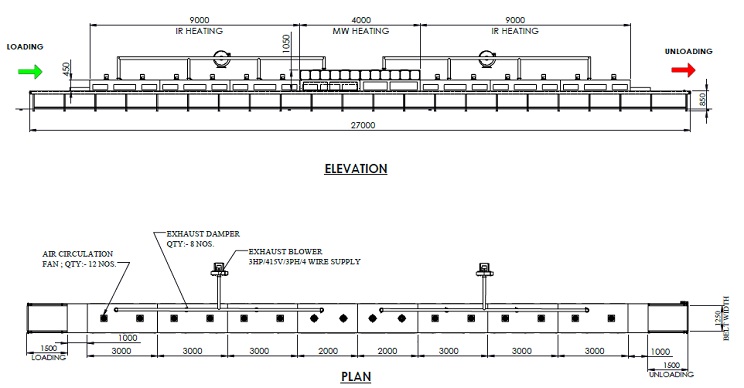

IR heating is a unique process; however, presently, the application and understanding of IR heating in food processing is still in its infancy, unlike the electronics and allied sector where IR heating is a mature industrial technology. It is further evident from this review that IR heating offers many advantages over convection heating. IR heating is attractive primarily for surface heating applications. In order to achieve energy optimum and efficient practical applicability in the food processing industry, combination of IR heating with microwave and other common conductive and convective modes of heating holds great potential. It is quite likely that the utilization of IR heating in the food processing sector will augment in the near future, especially in the area of drying and minimal processing.

Why choose us?

Accuracy, efficiency, machine quality and output quality are not just words but our commitment towards our profession since last 42 years, creating a base of more than 1000 loyal customers. Our Industrial Heating Systems can be used as application for heating the food products all with a level of precision that manufacturers demand. We also provide detailed assistance without much hassle of complex functioning and installation of the machinery. We always strive to achieve more than client satisfaction with our timely delivery, quality and efficiency towards every machine manufactured by us.