Food coating is the process of applying outer surface of liquid or powder on core eatable substance either to enhance the taste or increase the life of food. Increasing demand of packed foods, producing new and innovative style of serving eatables such as cereals, candies, chicken, hams, snacks, Cheese, chocolates and many more to market has increased the demand of coated food. The food coating is primarily depends on two key factors number one is the coating ingredient (liquid or solid), and number two is machinery that used for the coating process. The coating machine or coating process mechanical setup is very crucial and have to be designed by keeping end product at front. The Food coating processing setup is performing various activities from applying coating ingredient in the desired manner, keeping food substance in motion (keeping the line or process running) and in final stage solidifying the coat on the eatable substance and make the handling process easy.

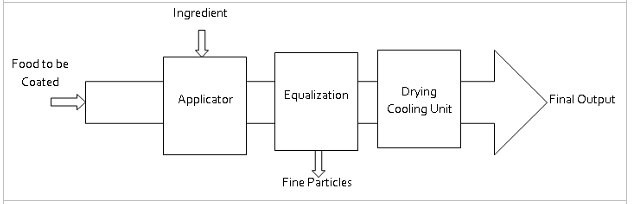

The coating process mainly comprise of following:

- Applicator: This section of coating machine applies the fine particle of the coating ingredients on the food product, the process of applying can be spraying, dipping, dropping and mixing.

- Equalization: This section of the coating processing machine tries to equalize, in simple words it tries to make the coating on the food as even as possible, by applying various techniques.

- Drying and/or Cooling: This section of complete process play very vital role in the life cycle of food coating process, the amount of heating and cooling is set to be one of the critical functions to harden the coated ingredient.

Coating systems are can be classified in two categories:

- Continuous Coating System

- Batch Coating System

Choice of appropriate coating system depends on the input food and ingredients in application, below are the criteria for selection:

- Food substance: Shape, Size, Weight, surface area

- Ingredient: Form Liquid or solid, viscosity, thickness, absorbing

- Coating layer thickness required

- Number of Coating cycle required

- Drying, Cooling, Freezing required

- Total capacity of machine

- Rate of output

Few of the common application of the food coating process are as follows:

- In Bakeries for coating of bread or doughnuts

- Sugar candy coating

- Snacks coating

- Dry fruits coating

- Chocolate coating

- Cereal Coating

- Dairy products coating Cheese, Butters and Etc

- Chicken Coating with Egg batter

- Nuggets

- Prepared vegetable

- Dragees