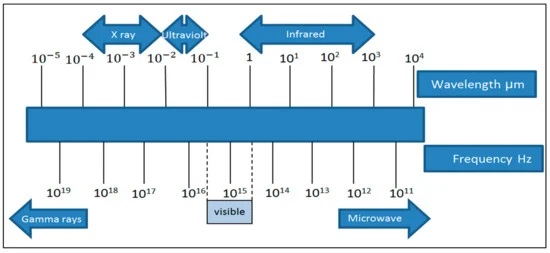

Energy conservation is one of the key factors determining profitability and success of any unit operation. Heat transfer occurs through one of three ways, conduction, convection, and radiation. Foods and biological materials are heated primarily to increase their shelf life or to boost taste. In conventional heating that is achieved by combustion of fuels or by an electrical resistive heater heat is generated outside of the item to be heated and is sent to the material by convection of hot air or by thermal conduction. By exposing an object to infrared (IR) radiation, the heat energy generated will be absorbed by food materials. Together with microwave, radiofrequency (RF), and induction, IR radiation transfers thermal energy within the form of electromagnetic (EM) waves and encompasses that portion of the EM spectrum that borders on visible radiation and microwaves. Bound characteristics of IR heating like efficiency, wavelength, and reflectivity set it except for and build it more effective for some applications than others. IR heating is additionally gaining popularity because of its higher thermal efficiency and quick heating rate/response time as compared to conventional heating. Recently, IR radiation has been widely applied to numerous thermal processing operations within the food industry like dehydration, frying, and sterilization.

The amount of the IR radiation that is incident on any surface has a spectral dependence because energy coming out of an emitter is composed of different wavelengths and the fraction of the radiation in each band, dependent upon the temperature and emissivity of the emitter. The wavelength at which the maximum radiation occurs is determined by the temperature of the IR heating elements. This relationship is described by the basic laws for blackbody radiation such as Planck’s law, Wien’s displacement law, and Stefan–Boltzman’s law.

The effect of IR radiation on optical and physical properties of food materials is crucial for the design of an infrared heating system and optimization of a thermal process of food components. The infrared spectra of such mixtures originate with the mechanical vibrations of molecules or particular molecular aggregates within a very complex phenomenon in overlapping.

The application of infrared radiation to food processing has gained momentum due to its inherent advantages over the conventional heating systems. Infrared heating has been applied in drying, baking, roasting, blanching, pasteurization, and sterilization of food products.

Drying and dehydration Infrared heating provides an imperative place in drying technology and extensive research work has been conducted in this area. Most dried vegetable products are prepared conventionally using a hot‐air dryer. However, this method is inappropriate when dried vegetables are used as ingredients of instant foods because of low rehydration rate of the vegetables. Freeze‐drying technique is a competitive alternative; however, it is comparatively expensive.

Application of FIR drying in the food industry is expected to represent a new process for the production of high‐quality dried foods at low cost. The use of IR radiation technology for dehydrating foods has numerous advantages including reduction in drying time, alternate energy source, increased energy efficiency, uniform temperature in the product while drying, better‐quality finished products, a reduced necessity for air flow across the product, high degree of process control parameters, and space saving along with clean working environment.

Two conventional types of infrared radiators used for process heating are electric and gas‐fired heaters. These 2 types of IR heaters generally fit into 3 temperature ranges 343 to 1100 °C for gas and electric IR, and 1100 to 2200 °C for electric IR only. IR temperatures are typically used in the range of 650 to 1200 °C to prevent charring of products. The capital cost of gas heaters is higher, while the operating cost is cheaper than that of electric infrared systems. Electrical infrared heaters are popular because of installation controllability, ability to produce prompt heating rate, and cleaner form of heat. Electric infrared emitters also provide flexibility in producing the desired wavelength for a particular application.

IR heating is a unique process; however, presently, the application and understanding of IR heating in food processing is still in its infancy, unlike the electronics and allied sector where IR heating is a mature industrial technology. It is further evident from this review that IR heating offers many advantages over convection heating, including greater energy efficiency, heat transfer rate, and heat flux that results in time‐saving as well as increased production line speed. IR heating is attractive primarily for surface heating applications. In order to achieve energy optimum and efficient practical applicability of IR heating in the food processing industry, combination of IR heating with microwave and other common conductive and convective modes of heating holds great potential. It is quite likely that the utilization of IR heating in the food processing sector will augment in the near future, especially in the area of drying and minimal processing.

We at KERONE have a team of experts to help you with your need for Infrared Heating in food industry in various products range from our wide experience.