Harvesting fruits and vegetables are hard efforts put by farmers, but maintaining it even equally difficult for them to reach from farm to plates. Maintaining a nutrition level is critical; the way to maintain is keeping fruits and vegetables fresh as low temperatures, which is not an easy task especially in the long supply chain. Mainly in developing countries, this becomes challenging to maintain the low temperature every time this results in the contamination of these fruits and vegetables. This such cases Drying comes in recuse, it is the oldest and most effective method of lowering water content to slow down food spoilage by micro-organisms.

Drying, dehydrating, and dewatering are terms used interchangeably. However, they can be differentiated by the level of water removed. Drying of food material occurs when water vapor is removed from its surface into the surrounding space, resulting in a relatively dried form of the material. In the process of dewatering,water is drained or squeezed out of the material. On the other hand dehydration evaporation of water takes place initially the surface water (external diffusion) then from the interior surface of raw material (internal diffusion). Shelf of dried food items was large than the non-dried one. The shift in focus of drying agriculture products has resulted in sophisticated drying/dewatering/dehydrating machines that are developing high quality dried fruits and vegetables.

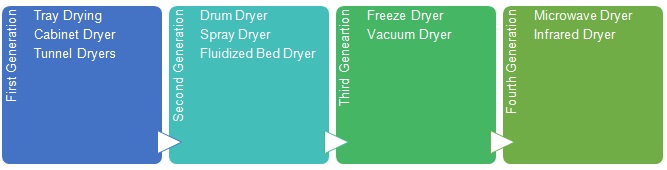

There has been tremendous advancement in the process of food and vegetable drying, the plethora of techniques have been developed and innovated over years, below are summary of few of commonly developed techniques, they can be classified in 4 generations:

- Tray Dryer : Tray dryers are amongst the oldest drying equipment, find application in agriculture dehydrating and drying.A tray dryer is an enclosed rectangular chamber in which trays are placed one below the other in a rack-type structure. The material to be dried is placed in a tray and the hot air is circulated in the chamber. The walls of the chamber are insulated properly to avoid any type of environmental heat loss. Hot air is continuously circulated within the chamber; convection heating takes place to remove the moisture contains from the wet material placed in trays. Blower fans are mounted within the chamber to ensure proper circulation and transfer of heat. The Control panel is fitted on the outer body of the chamber to control the temperature and drying speed.

- Cabinet Dryer : This one of the simplest types of the dryer, the name is given due to the enclosure provided for drying, where the material to be loaded in trays or trolley. Hot air is released from top or bottom even from side walls in some cases.

- Tunnel Dryers : Tunnel dryers brought huge changes and advantages into the food industry when brought in first in the early ’90s. These dryers are an advanced version of tray and cabinet dryers, it had capability where material placed in tray or trolley moved automatically through the tunnel.The material to be dried is fed from one end in the air heated tunnel for drying and collected from the other end. The name is derived due to its construction which looks like a tunnel. In tunnel dryer based on the selection of technology, the drying process can be completed while material transfers through a tunnel. Tunnel dryer commonly combined with the hot air as the source of drying of material, however, the advancement in the heating technology has enabled the tunnel dryer with advanced and faster drying techniques such as microwave/ RF/ Infrared. Typically tunnel consist of a door at one end that opened as closes when a material is to be fed, when a trolley is pushed or traveled in the tunnel then door get closed and the hot air is circulated within the tunnel with the help of fans, on completion of the drying process the outlet gate opens and the material is collected. Air movement, circulation, and heating methods vary in tunnel dryers. Three different arrangements, namely, counterflow, parallel flow, and combined flow.

- Drum Dryer : The drum dryer is very flexible in nature, its operation depends on the pressure of steam within the drum, speed of drum rotation, a width of an applicator, and the ratio of drum speed rotations. All these parameters can by a control/ regulated independently without any dependency on each other. A typical value of the drum dryer components ranges from steam pressure in the drum from 29 to 115 psi, rotation speed can vary from 2 to 30 rpm, thin sheet applicator width can be designed from 0.05 to 0.5 mm, and the ratio of drum rotation speed is from 1 to 5. Feed application in the single drum was dipping, splashing, spraying, and bottom feed roll. The feeding method is generally based on the viscosity of the feed. The drum drying parameters such as drying temperature, feed rate, rotation speed, feed concentration, and surrounding air condition are influential to the attributes of drum-dried food such as particle size, bulk density, moisture content, and solubility.

- Spray Dryer : Spray drying is a method of dehydrating fluids, solutions, and thin slurries, it converts the fluids or slurries to powder form. Liquid or slurry material to be dehydrated is sprayed in the form of a fine droplet dispersion into the hot airstream. Both air and material either travel in parallel or counterflow. Drying in a spray dryer occurs at a very fast rate so that the contact of material to heat is not for a longer time hence its does not damage the heat selectivity materials and becomes ideal for drying such materials.

- Fluidized Bed Dryers : Fluidized bed dryer provided the good solid mixing, high rate of heat and mass transfer and transportation of material. The fluidized bed dryer is more suitable for the drying of fine powder particle sizing from 10 to 2000 mm as compared to other conventional drying methods. A fluidized bed is achieved by passing a gas stream from the bottom of a bed of particulate solids. At the low velocity of the gas, the bed stays in a static condition, and the particles lay on a gas distributor plate. The fluidizing gas passes through the distributor and it is uniformly distributed across the bed. The gas velocity is increased such that to achieve the fluidization of bed, the gas velocity at which the bed achieves the fluidization is known as minimum fluidization velocity. A Fluidised bed dryer operates at a gas velocity higher than the minimum fluidization velocity of material under processing. This increase in the gas velocity result in the suspension of particles under processing in air, this appears as the boiling of solid particles of material under processing.

- Freeze dryer : Freeze-drying, also known as lyophilization or cryodesiccation, is the process of sublimation of ice from frozen material at reduced pressure. This is in opposition to other methods of dehydrating where the heat used to evaporate the water.

- Vacuum Dryer: In the vacuum drying process, the object to be dried is placed in an enclosed container to vent air and reduce the pressure by using vacuum pumps to increase the water vapor partial pressure difference. Early development of vacuum technology was done in conjunction with the freeze-drying for drying of various foods.Vacuum dryers have no air within hence there is no air pressure, so absolute pressure developed is water pressure.

- Microwave Dryer : Microwave based industrial dryers have been answered too many of such industrial drying application, it utilizes high-frequency electromagnetic waves that penetrate through the material and results in mobilizing the molecules from within which helps in achieving the goal of drying at a very faster rate. Microwave is not a type of heat, rather it’s a form of energy that is exhibited as heat by the means if their interaction with the material. It results in material to heat themselves, the mechanism of energy conversion used is dipole rotation. In Dipolar rotation is forced processing that happens within the material, many molecules such as water are having asymmetric i.e. they are randomly oriented being in relaxed (zero) state.

- Infrared Dryer : Infrared (IR) dryers are modern-day industrial drying solutions for material surface, Infrared (IR) dryer uses the infrared radiations, and Infrared radiations are invisible electromagnetic radiation whose wavelength is longer than the visible light wave range between 0.78 and 1000 µm. This type of radiation has characteristic to transfer thermal energy from warmer objects to cooler objects. The desired heat is produced at the surface of the targeted material; heat is produced on the surface by matching the infrared emission spectrum of the radiator to the absorption capacity of a material.

Agriculture and food safety has always been prime focused industry, due to increasing population and shrinking farming land, food safety has gained even more attention than ever before. Drying plays a vital role in keeping food items used for a longer period, hence this is a very important industry. We, companies such as Kerone always strive to achieve the best possible technology to support the agriculture and fruit and vegetable industry.