Spray drying has been employed in the food industry for concerning one hundred fifty years and is responsible for creating a number of the foremost essential ingredients and product within the food industry today—such as milk, instant low, and fine-grained flavors. Learn the key steps within the spray drying method, the highest advantages of this method, and the variables you should know for creating the perfect powder.

We encounter spray dried ingredients and food products all the time. Whenever a liquid has been converted to a shelf-stable powder, there’s a more better chance that spray drying was used. The most usually spray dried foods include:

- Milk Powders

- Dried Eggs

- Instant Coffees

- Instant Teas

- Dried Fruit Juices

- Honey Powders

- Molasses Powders

- Powdered Flavors

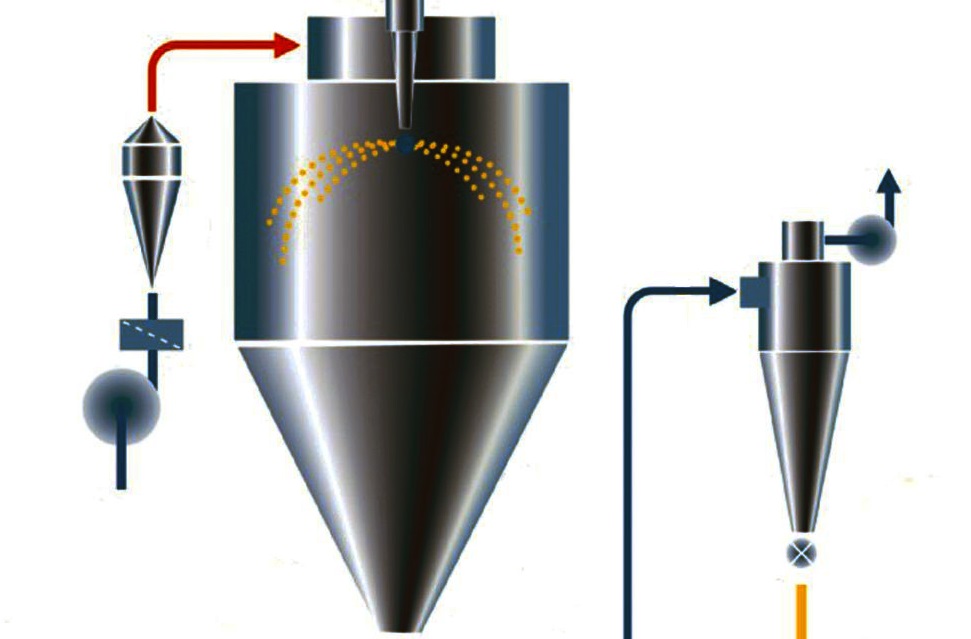

While there are many drying processes on the market for food, the spray drying method is distinguished by its unique equipment that enables for speedy drying with minimal heat exposure. In spray drying, a liquid is sprayed through atomizer into a chamber that contains streams of hot air. The moisture quickly evaporates, leaving behind solid powder particles that fall to bottom of the chamber.

Spray drying is ideal for heat-sensitive materials and whenever a free-flowing, uniform powder is needed. Whereas alternative drying techniques generally produces flakes that then should be ground to size, spray dryers create a free-flowing powder with a slim size distribution, making a subsequent grinding step unnecessary. Furthermore, spray drying is method of choice for commercial-scale encapsulation applications and is utilized to encapsulate flavors, carotenoids, and lipids.

The benefits of spray drying are:

- Appropriate for heat-sensitive foods

- Manufactures fairly uniform particle sizes

- Makes a free-flowing powder

- Efficient at encapsulation

Spray drying is a unique method of drying that depends on atomization to create a uniform, free-flowing powder and permits heat exposure to be kept to a minimum. The spray drying process consists of the following steps:

- Preparation of the liquid or slurry

- Adding the liquid feed to the spray dryer

- Atomization of the liquid feed to create droplets

- Drying of the droplets in a heated air stream

- Collection of the dried particles

Two Characteristics of Spray Drying are:

- Atomization

- Drying Kinetics

Atomization:

Atomization is the distinguishing feature of the spray drying process and plays a critical role in determining the quality of the finished product. It involves generating a vast range of droplets from a liquid stream, thus greatly increasing its surface area and allowing faster drying rate. For example, 1 m3 of a liquid can form 2×1012 droplets with a surface area of 60,000 m2.

Atomization can be accomplished through single-fluid nozzle, two-fluid nozzle, or rotary disc atomizers which manufacture droplet sizes from 10 to 500 µm (ideally 100 to 200 µm), depending on the feed consistency and composition.

When the atomized droplets come in contact with the heated air currents entering the chamber, a series of simultaneous heat and mass transfer processes takes place. Heat is transferred to the product to evaporate moisture, and mass is transferred as a vapor into the surrounding gas.

Drying Kinetics:

The drying method can be described as having two phases: the constant-rate period and the falling-rate period. In the constant-rate period, moisture evaporates quickly from a saturated surface via diffusion through the stationary air film at a rate sufficient to maintain saturation. In the falling-rate period and as moisture removal progresses, the solute dissolved in the liquid reaches a concentration beyond its saturation concentration to form a thin shell at the droplet surface.

Kinetically, this stage marks a transformation from low- to high-temperature drying. Following this, and depending on inlet temperature, feed consistency, and atomization variables, the droplets may follow one of two principal pathways, creating either small-dense or large-hollow particles. Dried particles are recovered with separation devices such as cyclones and bag filters or are scrubbed for further collection followed by cooling and packaging.

A number of variables influence the characteristics of the finished powder, including feed properties, type of atomizer used, and airflow factors

Optimizations of these variables are often achieved through a good understanding of the spray drying method to produce particles free of imperfections and with the required properties.

We at KERONE have a team of experts to help you with your need for Spray Drying from our wide experience.