Globally, industries are facing mounting pressure to decrease their carbon footprint, with the cement industry being a key player in this endeavor. Cement manufacture requires rotary kilns, which have long been linked to substantial carbon emissions. The cutting-edge tactics and technology used in rotary kiln operations to reduce CO2 emissions provide light on the critical stages towards sustainable industrial practices.

The cement business is essential to the building industry, and its effects on the environment are significant. Approximately 7% of all carbon dioxide (CO2) emissions worldwide come from the cement industry, making it one of the primary sources of emissions. The cement industry is becoming more interested in carbon capture technology as countries strive to lessen their carbon impact.

The cement industry’s potential for carbon capture technologies

Reducing emissions has gained global attention as people’s concerns about climate change grow. The cement industry is one of the major emitters of carbon dioxide, and carbon capture is one method of reducing emissions.

Reducing carbon footprints is a reason to note that carbon capture technology is becoming more and more valuable. In this regard, the cement sector is one of the primary objectives of carbon capture, use, and storage (CCUS), which is crucial in the battle against climate change.

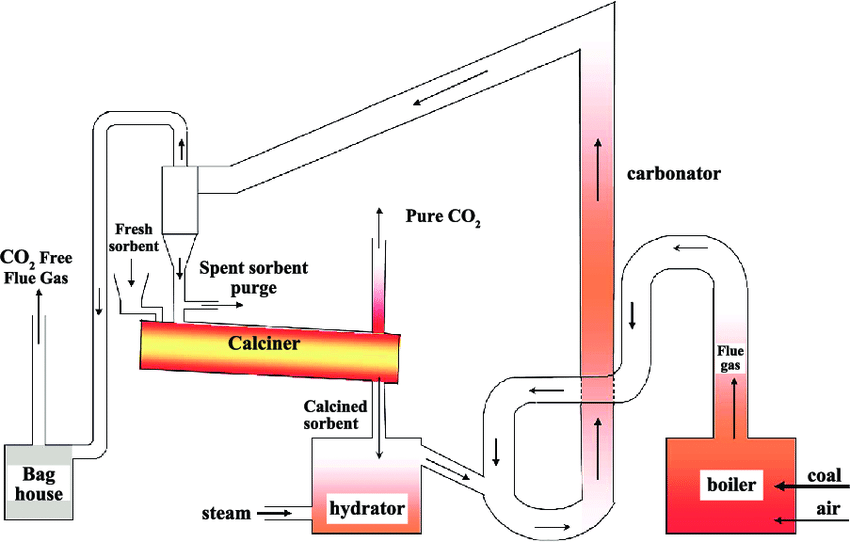

Many carbon capture systems are in development, such as membrane separation, calcium looping, and oxyfuel cement kilns.

In the cement industry, oxyfuel cement kilns are currently thought to be the most promising technology for storing and capturing carbon. The concentration of CO2 in the exhaust is increased in an oxyfuel cement kiln by adding pure oxygen to the kiln instead of air, which facilitates its collection.

But the technology is still in its infancy and needs further investigation and advancement. Recovering CO2 from the cement production process is just the initial stage. The next action is to figure out how to use or store the CO2 that was caught. One possibility is to create useful goods out of the CO2 that is collected during the cement making process.

What are the principal obstacles and prospects associated with the use of carbon capture technology in the cement sector, though?

The primary obstacles to integrating carbon capture in the cement sector

The high cost of carbon capture technology is one of the biggest obstacles to its implementation in the cement industry. One of the main obstacles to the technology’s extensive commercial adoption has been the expense of carbon capture and storage.

Furthermore, finding storage locations for the collected carbon dioxide is difficult due to the massive size of cement manufacturing, and transporting the carbon dioxide can be expensive.

A further obstacle facing the cement industry is the absence of rules and incentives pertaining to carbon capture and storage. Globally, governments are enacting laws that provide tax breaks, grants, and subsidies as incentives for reducing greenhouse gas emissions.

Cement businesses, on the other hand, are at a disadvantage when compared to industries that generate fewer greenhouse emissions since these rules frequently overlook the high cost of carbon capture and storage.

Carbon capture offers numerous prospects in the cement sector, despite certain obstacles. The collected carbon dioxide may bring in more money if it is used to other industrial operations like fuel or chemical production.

Furthermore, cement businesses may be able to achieve future emissions requirements by investing in carbon capture technology, avoiding the need for more expensive and major adjustments down the road.

Carbon capture technology is essential for lowering CO2 emissions from the cement industry and preventing global warming. In general, reducing carbon dioxide emissions from the cement sector is essential to the battle against global warming. Technology that uses carbon capture presents a viable way to cut emissions.

Although there are still obstacles to be solved, cement producers and the environment stand to gain greatly from the advancement of carbon capture and storage technology. The cement sector will be essential to the shift to a sustainable and clean future, and carbon capture technology will be a critical differentiator for the sector’s survival in the years to come.

With our extensive expertise, we at KERONE have a team of professionals to assist you with your requirement for a kiln or rotary dryer in a variety of product ranges. We produce and distribute a variety of industrial gear and equipment.