The preparation ways of biochar are primarily divided into pyrolysis, hydrothermal carbonisation (HTC), and microwave carbonisation. Different preparation ways affect the physical and chemical properties of biochar, such as yield, ash, specific surface area, pore structure, type and variety of useful groups, and cation exchange capacity. Compared with the pyrolysis, HTC doesn’t need drying step and includes a higher biochar yield. The benefits of microwave carbonisation are manageable method, no hysteresis, fast heating, and energy efficient. However, biochar prepared through HTC and microwave contained high concentrations of organics, that don’t seem to be actually considered soil remediation material.

Pyrolysis

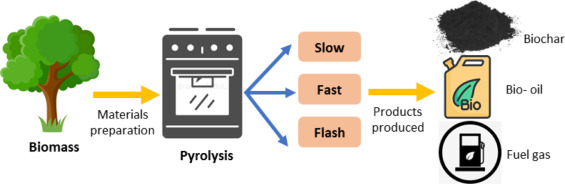

Pyrolysis, also known as the thermal decomposition below oxygen-free conditions, is the most typical technique for preparing biochar. In general, pyrolysis involves the heating of organic materials to temperatures greater than 400c below inert atmospheres by electric heating or high-temperature medium. There are several parameters influence physicochemical properties of biochar, like raw material, reaction temperature, heating rate, duration, and reaction atmosphere.

Factors Affecting the Pyrolysis Process

The raw materials for the preparation of biochar are abundant. Basically, any type of organic materials can be pyrolyzed. because of the massive output of biomass solid waste resources, biomass is a common raw material for biochar, primarily including wheat straw, corn straw, wood chips, melon seed shell, peanut shell, rice husk, livestock and poultry manure, kitchen waste, sludge, fruit skin, etc. Biochar prepared from totally different materials contains different proportions of cellulose, hemicellulose, and lignin, therefore its yield, component composition, and ash content are totally different.

According to the different heating rate, it could be divided into slow pyrolysis (SP) and fast pyrolysis (FP). SP is characterized by slow heating (minutes to hours) of the organic material in the oxygen-depleted atmosphere and relatively long solids and gas residence times. During the SP process, liquid and solid products such as char, bio-oil, and syngas (CO, CO2, and H2) are produced. The FP involves blowing small particles of organic material into a thermal reactor and exposing it to heat transfer in milliseconds to seconds. Modern FP often takes place in fluidized bed systems, systems using ablative reactors, and systems using pyrolysis centrifuge reactors (PCR). Slow and fast pyrolysis results in biochars with different physicochemical properties, thus providing different effects on the soil environment upon application.

The reaction atmosphere studied by researchers is dominated by inert gases, such as N2, Ar, that principally act to isolate oxygen. Besides, the atmosphere of co2, H2O, NH3, and O3 is also utilized to prepare biochar that is called as physical activation, also known as gas activation. The gases selectively decompose the non-structural elements of the biochar surface, open its internal pores, and increase the particular surface area and pore volume.

Other New Methods

In addition to the pyrolysis, hydrothermal carbonization, and microwave carbonization discussed above, flash carbonization and Torre faction are other methods of biomass transformation. During the flash carbonization process, the flash fire is ignited at a high pressure (1–2 Mpa) on the biomass packed bed to convert the biomass into the gas and solid phase products. It is reported that about 40% of biomass is converted to solid phase products (biochar) at 1 Mpa. In addition to microwave, new pyrolysis technologies such as laser and plasma cracking technologies have also been developed. The sample usage of laser pyrolysis technology is small, and rapid heating and cooling can be carried out, which can effectively avoid the occurrence of secondary reactions. Plasma pyrolysis technology is mainly applied in the preparation of syngas and coke. Compared with the traditional cracking technology, it can greatly increase the syngas and reduce the yield of bio-oil. However, it is difficult to popularize the new pyrolysis technology due to its high cost and energy consumption.