The present competitive manufacturing environment demands that throughput is not a mere performance measure, but it is a key to business survival. The conventional heating technologies like convection and conduction find it difficult to meet the high-volume industrial needs and, in many cases, they result in bottlenecks during the production process, the production of poor quality and the consumption of a lot of energy. The sophisticated microwave heating devices are re-establishing the speed, efficiency and scalability of industries.

Supported by successful industrial implementations and active research and development, domains such as Kerone are facilitating this change through offering high-performance microwave technologies that are developed to support continuous high-throughput processing.

Understanding Microwave Heating in Industrial Environments

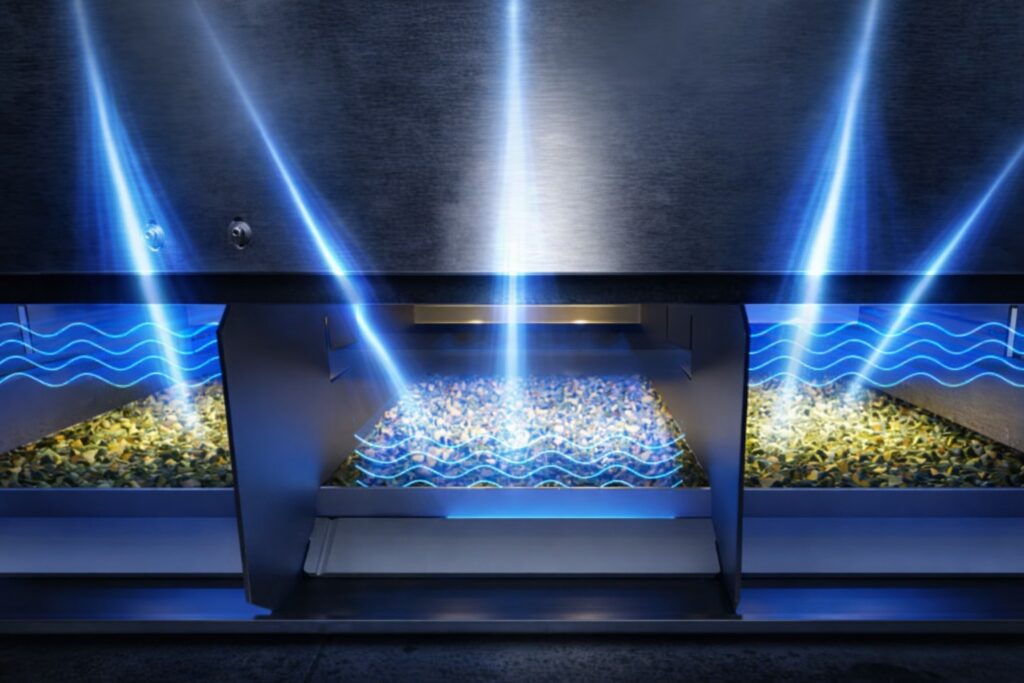

The microwave heating process provides internal energy in the material as opposed to conventional heating, where the heat on the surface is forced into the material.

Polar molecules interact with microwave energy, resulting in fast oscillation and heating. The outcome is the shortening of the cycle times, lowered thermal gradients, and increased repetition of processes. Frequencies up to 915 MHz are used in industrial-scale applications where deeper penetration of bulk material is desired, but frequencies up to 2.45 GHz are also used to provide deeper penetration on thin or surface-based processes.

The advantage of Microwave Heating over Traditional Thermal Systems

1. Acceleration of Speed and Throughput

Microwave systems have the ability to heat, dry, or cure faster than other methods and thus suppliers can produce more without adding more floor space or more shifts. This is why microwave heating would be a strategic choice when it comes to high-volume operations.

2. Sustainability and energy Efficiency

Microwave systems save a great deal of wasted energy by heating the product only, not the air or the equipment around the product. According to many plants, the energy saved is up to 70 percent as opposed to hot-air or steam-based systems and this is in line with the principles of sustainability and cost reduction.

3. Consistent Quality with Minimal Scrap

Even in-house heating reduces hotspots, cracking and stress of materials. This causes an increase in the first-pass yield rates, less rework, and uniform product quality, which is essential in large-scale industries.

Core High-Throughput Industrial Applications

- Continuous Drying and Moisture Removal: Microwave tunnel systems are superior in the drying of ceramics, chemicals, biomass, and food products. The inner seepage eliminates the hardening and cracking of the surfaces and allows the surface to be processed more rapidly by the conveyor with foreseeable outcomes.

- Rapid Curing of Composites and Coatings: Microwave curing is used in the production of automobiles and aerospace and in the production of advanced materials to shorten cross-linking of the polymer to a few minutes instead of hours and enhance the mechanical properties.

- Large-Scale Sterilization and Pasteurization: High-volume sterilization of foods, pharmaceuticals, and spices is using microwave heating. The technology removes microbes in a short time without destroying nutritional or chemical values.

Smart Integration: AI, ML and IoT Microwave heating systems

The current industrial microwave systems are no longer single standalone machines but intelligent, linked assets. With the use of AI algorithms, machine learning models, and IoT sensors, manufacturers will be able to see, in real-time, and have some adaptive control over the heating processes. Sensors and predictive analytics are useful to determine how the systems can automatically change the amount of power, conveyor speed, and exposure time based on the behaviour of materials.

Engineered to be Reliable, Scalable and Controllable.

Modern microwave systems used in industries are characterized by modular generators, solid-state power sources and safety interlocks. This modularity enables the plants to increase capacity gradually without going offline, which is a critical requirement in a production facility that operates 24/7.

Being a reputable Manufacturer and having a record of decades of experience in the industrial heating sphere, Kerone Engineering Solutions Ltd. prepares systems that would perfectly fit the current production lines. Performing as a supplier with a technology orientation, we guarantee reliability in the long term by the support of strong engineering, service and specific customization of the application.

High-Volume Manufacturing: ROI and Business Impact

- Rapid Payback by increased output: Microwave systems are frequently able to provide ROI in 12 to 18 months by reducing cycle times and throughput and enhancing throughput. Increased capacity utilization also corresponds to revenue potential.

- Lower Operating Costs: Distributed heating minimizes the use of power and servicing needs. To a large number of users, this translates to a long-term lowering of the operating costs.

- Quality-Driven Profitability: Equal heating decreases scrap rates and enhances customer satisfaction, which is very crucial in competitive, high-volume markets.

Conclusion: The Future of High-Throughput Processing

Microwave heating systems have solidly changed experimental technology to industrial strength. They provide a clear competitive advantage to manufacturers who have to meet increasing production demands, energy limitations, and demands on quality by providing quicker cycle time, constant processing, and quantifiable cost reductions. On the one hand, microwave heating, as compared to other traditional ways of heating, does not disrupt continuous processes and can be extended on a large scale without affecting its reliability or sustainability.

Kerone Engineering Solutions Ltd. solutions can enable future-proofing of the work of manufacturers by integrating cutting-edge microwave engineering with intelligent automation, data-driven control, and Industry 4.0 preparedness. The outcome is not only an increased throughput but also intelligent, clean and robust production lines.

With the trend of global industries towards efficiency, accuracy, and a sustainable process microwave heating is at the centre of the next generation processing. In the context of organizations that are willing to lead and not follow, a strategic move in the long-term competitiveness and operational excellence is the adoption of microwave technology in the present day.