Powdered milk or dry milk is a produced dairy product made by dehydrating liquid milk through many drying processes till it’s a powder. One purpose of drying milk is to preserve it; dried milk contains a way longer shelf life than liquid milk and doesn’t required to be cold.

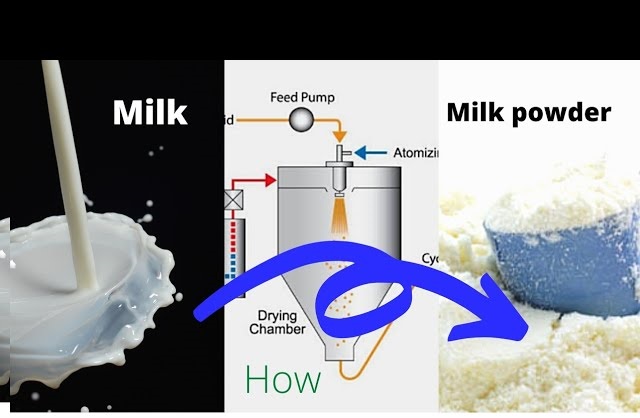

Milk powder manufacture is a simple and direct method able to be performed on an outsized scale. Production involves the gentle removal of water at the bottom attainable value under rigorous hygiene conditions whereas retaining all the required natural properties of the milk like color, flavor, solubility and nutritional value.

Whole (full cream) milk contains about 87 percent water. Skimmed milk contains about 91 percent water. During powdered milk production water is removed by boiling the milk below reduced pressure at low temperature in a method called evaporation. The resulting focused milk is then sprayed in a fine mist into hot air to get rid of any moisture so forming a powder. Approximately 13 kilogram of whole milk powder (WMP) or 9 kilogram of skimmed milk powder (SMP) can be made of 100 liters of whole milk.

Optimum dryer performance can be attained by monitoring the inlet and outlet flow to and from the dryer. Both, air temperature and relative humidity are measured.

In most cases two probes are installed on each dryer. One is installed on the inlet and one on the outlet exhaust. The relative humidity and temperature measurement will then be used to balance the dryer for optimum drying, thus reducing energy costs.

Spray drying involves atomizing the milk concentrate from the evaporator into fine droplets. this can be done inside an oversized drying chamber in a flow of hot air (up to 200 °C) utilizing either a spinning disk atomiser or a series of high pressure nozzles. The milk droplets are cooled by evaporation and they never reach the temperature of the air. The concentrate is also heated prior to atomization to reduce its viciousness and to extend the energy available for drying. Much of the remaining water is evaporated within the drying chamber, leaving a fine powder with around 6 percent moisture content with a mean particle size usually of <0.1 mm diameter. Final or “secondary” drying takes place in a fluid bed, or in a series of such beds, in which hot air is blown through a layer of fluidized powder removing water to the point of a moisture content between 2-4%.

Milk powders are vastly more stable than fresh milk however protection from moisture, oxygen, light and heat is required so as to maintain their quality and shelf life. Milk powders readily take up moisture from the air, resulting in a speedy loss of quality and caking or lumping. The fat in WMPs will react with oxygen within the air to provide off-flavors, particularly at higher storage temperatures (> 30°C) like found within the lower latitudes of the Tropics. Milk powder is packed into either plastic-lined multi-wall bags or bulk bins.

We at KERONE have a team of experts to help you with your need for spray drying solutions in various products range from our wide experience.