Poultry litter is a nuisance, particularly once you don’t treat it well and leave it wet on a pile in or outside your poultry house. It releases high levels of ammonia inflicting poor environmental conditions for the birds and the employees inside the house as well as for the neighbors. Additionally, ammonia is seen as a gas that harms the environment and for that reason governments impose minimizing the discharge of this toxic gas into the atmosphere.

Flies like wet litter and find it a perfect place to multiply, which in turn is not really appreciated by farm workers and people living in the vicinity. It is for these reasons that there is increasing interest by medium and large scale poultry producers to dry poultry droppings in as well as outside the poultry house. Most poultry housing systems offer the possibility to dry the droppings at the manure belt inside the house. These systems however have limited capacity and tend to create a lot of dust. Therefore some poultry farmers opt to dry the manure outside the house. They transfer the manure every one or two days from the poultry house to reduce the release of ammonia and the production of dust and moist in the poultry house. By drying the manure in a conditioned environment, where ammonia and dust can be captured, less energy is required.

There are a number of systems on the market to dry poultry manure outside the egg production facility. They all have their own advantages and disadvantages. KERONE is involved in the installation of numerous large and smaller scale poultry projects, introduced a while ago their own ‘KERONE’ poultry manure drying system. The development of this system started in cooperation with experienced engineers involved in the development of other manure drying systems. The KERONE manure drying system is usually placed in a separate area next to the poultry house. It consists of one or more tiers with direct chain driven revolving galvanized and powder coated steel plates. These plates are perforated, 35% of the surface is open, allowing air to go through for fast and better drying of the manure. The chain runs on a rail and moves the plates in such a way that no manure can get in contact with and harm the moving parts. The unique guide system, combined with a direct chain driver assures a trouble free motion.

The droppings, coming from the manure belts in the poultry house is equally distributed over the rotating top layer of the manure drying tunnel. As soon as the manure reaches the top of the primary layer the perforated plate tilts and drops the manure automatically on the plates of the level below to continue its way in the opposite direction through the tunnel to unleash a lot of moisture. Forced tilting of the perforated drying plates at every level guarantees no clogging and no manure sticking on the plates.

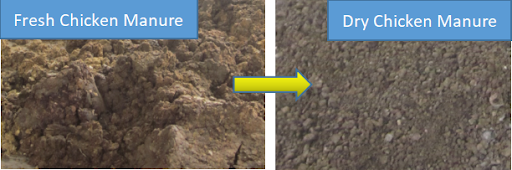

The ventilation air is blown at high pressure through the system to achieve a dry matter content of 80-85% in less than 72 hours, depending on the atmospheric humidity. During this method the discharge of fi ne dirt is reduced by about 70th. Experiences have learned that the method needs low energy consumption and may be easily and flexibly controlled by a touch screen. The system is simple to install up to a maximum length of 40 meters that equals a capability for drying manure of 200,000 layers. Drying manure to over 80th dry matter content reduces odour, ammonia and fly issues to a minimum and leaves a product that can be simply sold in containers or in bags as a fertilizer for field crops. It also can be pelleted to make it even more engaging to gardeners.

Here’s a glimpse of KERONE team in action, creating the perfect drying system to meet your industrial needs.