Atmospheric thermal plasma (ATP) has emerged as a promising technology with diverse applications across various industries, including the food sector. This comprehensive review delves into the advancements, challenges, and potential of ATP in food processing and preservation. By examining recent studies and technological developments, this review elucidates the mechanisms underlying ATP treatment, its effects on food properties, and its potential for enhancing food safety, quality, and sustainability. Furthermore, it explores the current limitations and future directions for harnessing ATP technology in the food industry.

Food safety is a major concern for food industries, regulatory agencies and consumers. Food- borne pathogens and spoilage microorganisms are problematic microbes in food industry due to their significant negative impact on public health and economy. There are a lot of sterilization methods to eliminate these microorganisms. Some of these methods rely on lethal heat treatment such as steam pasteurization, autoclaving, ohmic heating, etc. Thermal technologies have side-effects on nutritional, sensory and functional properties of treated foods, so alternative non thermal pasteurization methods such as high hydrostatic pressure, pulsed electric field, oscillating magnetic field, ionizing irradiation and high power ultrasound have been developed and studied in recent years. These processes retain quality of foods better than conventional methods; however, they have their own drawbacks. They are costly and required specialized equipment and trained personnel. Moreover, consumer acceptance and safety issues should be considered. Non thermal plasma is a new discipline in food processing. Plasma is electrically energized matter in a gaseous state that can be generated by electrical discharge. Electrical discharges in atmospheric pressure and low temperature make this process practical, inexpensive and suitable for decontamination of products where heat is not desirable.

Plasma is ionized gas that consists of a huge number of various species like electrons, positive and negative ions, free radicals, and gas atoms, molecules in the ground or excited state and quanta of electromagnetic radiation (photons). It’s considered to be the forth state of matter in the world.

It may be generated in the massive range of temperature and pressure by means of coupling energy to gaseous medium. This energy may be mechanical, thermal, nuclear, radian or carried by an electrical current. These energies dissociate the gaseous molecules into assortment of ions, electrons, charge – neutral gas molecules and different species.

Depending on the type of energy supply and quantity of energy transferred to the plasma, density and temperature of the electrons are modified. These lead Plasma to be distinguished into 2 groups, high temperature plasma and low temperature plasma.

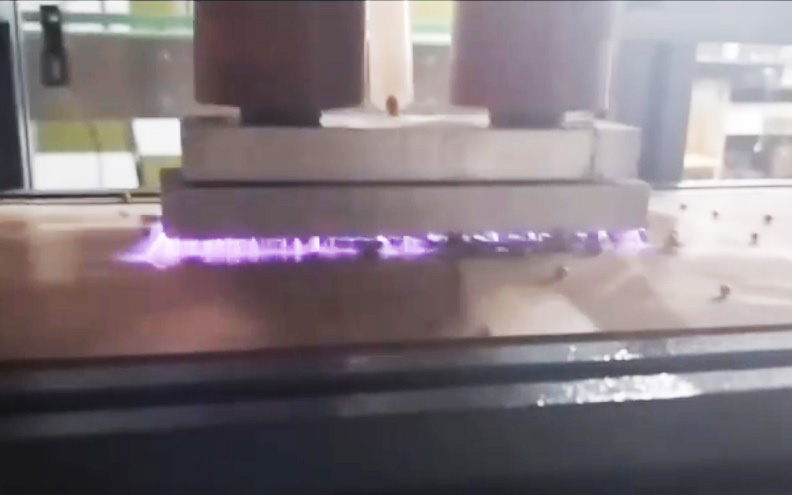

Low pressure glow discharge plasmas are of great interest in microelectronic industries but their vacuum equipment limits their application. Therefore one of the recent challenges was developing new plasma sources that can operate at or near 1 atmospheric pressure. Power sources of atmospheric pressure plasma generation can be microwave, RF (radio frequency), pulsed, AC (alternating current) or DC (direct current). Devices that have been used for plasma generation are the corona discharges, micro hollow cathode discharges, gliding arc discharge, one atmospheric uniform glow discharge, dielectric plasma needle, barrier discharge (DBD), atmospheric pressure plasma jet (APPJ). Among all, DBD and APPJ are commonly used in industrial applications like lightening, surface modification, etching and deposition.

APP is a rising non-thermal technology for reducing microorganism population on the surface of fresh and processed foods. Various reactive spices of plasma interact to biological cell to cause changes on cell wall and morphology of the microorganisms that result in death. due to the limit info regarding the nutritional and chemical changes in food products treated with this technology, specially, sensitive food that has high quantity of lipid and vitamins additional problems regarding food quality and safety should be considered.

Atmospheric thermal plasma represents a promising frontier in food processing and preservation, offering unique advantages in terms of rapid, uniform, and chemical-free treatment. By understanding the fundamental principles and exploring innovative applications, ATP technology has the potential to revolutionize the food industry by improving safety, quality, and sustainability. However, further research and development efforts are needed to overcome existing challenges and unlock the full potential of ATP for food applications.