IR radiation releases energy in electromagnetic wave form in the spectrum from 0.75 μm to 1,000 μm. The wavelength of IR usually is further classified into 3 ranges, namely, near-IR (0.75 μm to 1.4 μm), medium-IR (1.4 μm to 3 μm), and far-IR (3 μm to 1,000 μm). Principal food elements, including water, organic compounds, and biological polymers, absorb IR radiant energy efficiently in the wavelength range of 2.5 μm to 10 μm through changes in molecular vibration states, that corresponds to the medium- and far-IR regions. Hence the medium- and far-IR radiation will be efficiently used for thermal processing of food and agricultural product.

The advantages of utilizing IR for heating include no need for heating medium, high heat delivery rate, reduced usage of water and chemicals, improved energy and processing potency, reduced equipment footprint, and increased productivity, while at an equivalent time delivering prime quality and safe processed foods.

IR heating is most suitable for heating thin layers of food materials. The IR radiation does not penetrate deeply and heats only a few millimetres below the surface of foods. The absorbed energy can then be conducted to other areas within the food; however, as the sample volume increases, the conduction is limited.

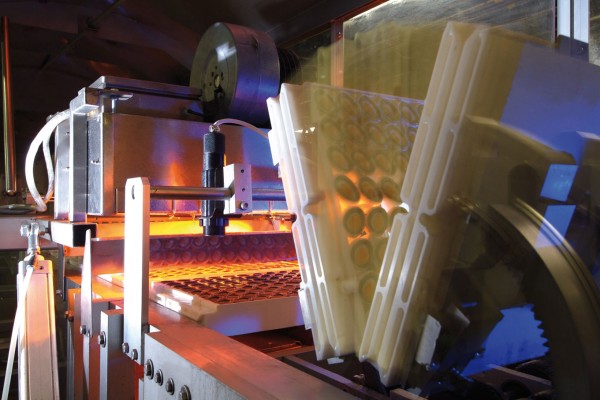

Based on the energy source, 2 forms of IR emitters are utilized in the food industry, particularly electric IR emitters and gas-fired IR emitters. Electric IR emitters have a metal filament placed within a sealed enclosure that’s either evacuated or filled with inert gas. Radiant energy in these heaters is generated by passing electric current through high-resistance wire. The component and the material surrounding the component are heated to an incandescent temperature. By modulating the power output, the spectrum of wavelength of these electric IR emitters is varied. The available forms of electric IR radiant emitters include reflector-type incandescent lamp, quartz tube, and resistance components. Advantages of electric IR emitters include prepared availability, easy management, instrumentation, and possibility for wide variety of heating components. Additionally, electric IR emitters generate zero emissions. However, electric-powered IR processing is expensive due to the high cost of electricity.

Alternatively, different types of gas-fired IR emitters, including direct-flame IR radiator, ceramic burner, metal fiber burner, high-intensity porous burner, and catalytic burner, are available. Combustion of air and fuel takes place on the burner surface in gas emitters and that results in an increase in the surface temperature and emits radiation in the wavelength range of 1.6 μm to 10 μm. Natural gas or liquefied gas (propane) can be used for heating perforated ceramic surface or steel tubes that emit radiation. High-moisture substances can absorb more radiation emitted by this class of IR emitters. One advantage of the gas-fired IR emitters is that they are not dependent on electricity, and thus cheaper in terms of operating cost. They are also capable of saving energy and are more reliable and durable than electric IR emitters. However, the initial cost of a gas-fired IR emitter is higher than electric IR emitters. Operating gas-fired IR emitters with flame also requires thorough ventilation to reduce hazards of evolved carbon monoxide. Alternately, flameless catalytic gas-fired emitters are available; these release IR energy through exothermic catalytic chemical reactions of natural gas. With catalytic burners, natural gas combines with air across the platinum catalyst and reacts by oxidation-reduction to yield a controlled bandwidth of IR energy and small amounts of CO2 and water vapour.

Applications of Infrared Heating in Food Processing

IR heating was 1st used industrially in the 1930s for automotive curing applications and rapidly became utilized in the manufacturing and therefore the electronics industry. in the last twenty years, thanks to vital progress in better understanding the mechanism of IR heating coupled with enhancements in the design of IR emitters, IR processing applications in the food industry are realized. The food industry currently uses IR for baking breads and baked goods, roasting nuts, and browning meats and other foods. Newer applications that are still under development include the following.

- Infrared blanching.

- Infrared drying.

- Infrared peeling.

- Infrared for microbial inactivation.

Although IR heating isn’t appropriate for all food heating processes due to its restricted penetration depth, it will provide significant advantages for processing foods in specific applications. it’s anticipated that application of IR in food processing for surface heating applications will still grow during the years ahead. it’s also anticipated that management of the IR spectrum utilized when heating will be tailored to specific food processing needs in the future, providing selective heating and optimum response.