Drying is a vital unit operation needed in food process industries, significantly in the dry fruits trade. Drying of almonds exhibit several characteristic options like non-spherical form, swelling/ shrinkage as a function of moisture content, uneven drying due to their peculiar form and proximity to alternative almond kernels and so on. The drying of almonds through experiments and process modeling. Moisture analyser unit was utilized to conduct experiments for one almond kernel. In this widely used equipment, internal air flow patterns and therefore heat and mass transfer depend upon natural circulation of air a detailed 3 dimensional computational fluid dynamics (CFD) model was utilized to simulate the air flow pattern, heat and mass transfer in the drying unit. Carefully 212designed experiments with one almond kernel were carried out at totally different temperatures to estimate key parameters of interest (drying mechanics and effective diffusivity). The CFD model was conjointly utilized to quantify non-uniform heat and mass transfer and thus non-uniform drying of one almond kernel.

Drying is an indispensable unit operation in many food processing applications. Drying of a variety of food product is carried out to reduce their moisture levels in order to increase the shelf life, reduce the probability of developing fungi and to facilitate further processing to obtain the final product. In particular most of the dry fruits are seasonal in nature, which requires appropriate post-harvest storage for a long duration of time. Therefore it is important to understand the influence of key process 2 parameters on drying of dry fruits. Almond is one of the widely cultivated and consumed dry fruit across the globe. It is important to ensure appropriate drying of almonds as more than desirable moisture will increase possibility of developing fungi, and over drying will adversely impact the economics, due to loss of weight.

Dried almonds (California grown) were obtained from local market. Almonds of similar size and each weighing around 1 gram. Were segregated and used for the experiments. Drying experiment was carried using single almond kernel. Almonds were initially dried till the weight was constant (change less than 0.1% in an hour at 120 o C) to determine the dry weight for each almond. In order to obtain initial high moisture content, each almond was soaked in 100 ml distilled water for a period of eight hours. As almonds surface have wrinkles, soaking the almonds also help to make the surface smooth.

The top almond surface which receives the infrared radiation of lamp directly and is exposed to upward airflow has the maximum heat transfer coefficient value. As the almond surface has a curvature, central top region has the maximum heat transfer coefficient values. Bottom almond surface has relatively lower values of heat transfer coefficient which is expected.

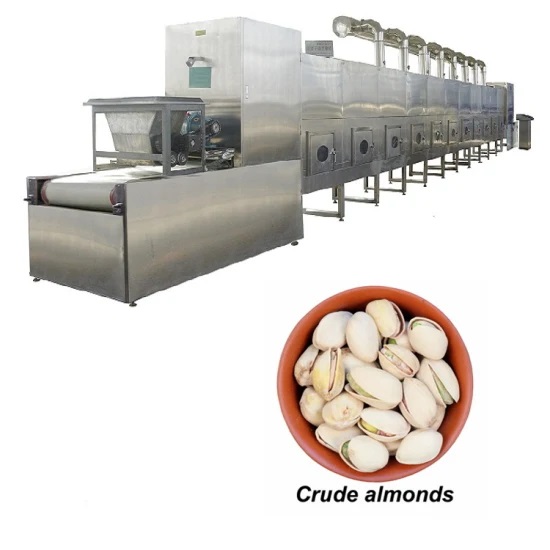

We at KERONE have a team of experts to help you with your need for drying of almonds and walnuts in various products range from our wide experience.