Conventional rice drying is performed using heated air that transfers energy to the surface of grain kernels by convection. The energy transfer within the kernel is done by conduction. Water is desorbed into the drying air from the kernel surface, and a moisture gradient is established within the kernel, with water molecules diffusion toward the surface. The drying air temperature increase enhances the water desorption rate from the kernel surface, which results in a greater moisture gradient inside the kernel. Since a high internal moisture gradient can result in cracked or broken kernels, there is a practical upper limit of the drying temperature that can be used. Commercial dryers generally operate at temperatures around 60◦ C and use the multiple passes through the dryer.

Microwave drying differs fundamentally from the conventional hot-air grain drying. During microwave drying, microwave energy is transmitted by waveguides into the chamber that contains the dried material – rice kernels. Microwaves penetrate the rice kernel, where highly polar water molecules preferentially absorb them. The high-energy water molecules rapidly diffuse through the rice kernel to the surface where they desorb.

The intensification of microwave drying can be achieved in combination with vacuum drying. The reduced pressure in the vacuum chamber lowers the concentration of water in the air surrounding the grain, thereby increasing the rate at which the water molecules desorb from the kernel surface. For a given rate of drying, reduced pressure lowers the temperature at which the grain is dried compared to the conditions required for drying at atmospheric pressure. Moisture is removed from the drying chamber by a vacuum and condenser. During microwave vacuum drying the moisture gradient within the rice kernel remains, but its magnitude is considerably lower than at conventional drying.

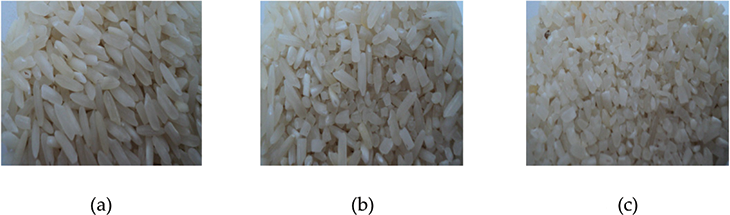

The most important application of microwave rice drying is the process of rice parboiling. Using microwave-vacuum procedure for parboiled rice drying and investigated the effect of the process conditions (soaking, steaming, microwave power output, drying pressure, drying time, final moisture content) on the rate and efficiency of drying. The rice kernel drying rates were directly proportional to microwave power output and inversely proportional to the dryer operating pressures. (https://johnsonchimney.com) At given conditions the drying rates were constant until the rice moisture content fell below 16 %. Parboiled rice could be rapidly dried up to the moisture content of 16 % without any significant affect on milling yields. However, below this value, head rice yield was highly dependent on the drying rate. Head rice are unbroken, whole kernels of rice and broken kernels that are at least three-fourths the length of an average unbroken kernel.

The effects of microwave drying on milling output and technological properties (cooking and compositional quality) of milled rice. The authors found a significant negative correlation between the amount of head rice and duration of drying and a positive correlation between the drying time and the number of broken grains. Microwave drying resulted in a significant decrease in amylose content in a high amylose variety. Neither significant differences in proteins, fat, and ash contents were noted for both high and low amylose varieties, nor the microwave drying time significantly affected the optimum cooking time of the parboiled rice.